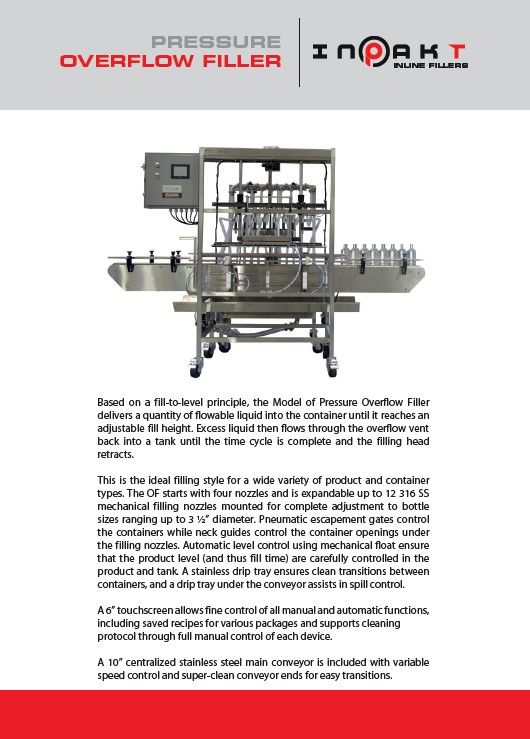

Pressure Overflow Filler

- Fill-to-level principal

- Model OF Pressure Overflow Filler delivers an abundance of flowable liquid into the container until it reaches an adjustable fill height

- Excess liquid then moves through the overflow vent back into a tank until the time cycle is complete and the filling head retracts

- Ideal filling style for a wide variety of product and container types

- Starts with four nozzles and is expandable up to 12 x 316 SS mechanical filling nozzles all mounted for thorough adjustment to bottle sizes ranging up to 90 diameter.

- Pneumatic escapement gates ensure the containers are aligned while the neck guides control the container openings under the filling nozzles

- Automatic level control using mechanical float allow the product level (therefore fill time) to be closely controlled in the product as well as tank

- Stainless drip tray establishes clean transitions between containers

- Drip tray under the conveyor assists in spill control

- 150mm touchscreen ensures fine tuning of all manual and automatic functions, including saved recipes for various packages and supports cleaning protocol through full manual control of each device

- 255mm centralized stainless steel main conveyor is included with variable speed control and super-clean conveyor ends for quick and simple transitions

- Fully adjustable escapement gates with counting photo-eye for container detection

- Fully adjustable 316 SS filling nozzles

- Integrated drip tray and neck centering guides

- 230L product tank (may be sized differently)

- Centralized main conveyor motor allows configurable conveyor with clean transitions

- Fully stainless steel frame

- 150mm touchscreen interface

- Speeds to 60 cpm based on product and size

- Integrated container rinser can be added to the infeed end to wash out containers

- Rinser is controlled with the touchscreen and works together with the filler

- Integrated Air Cleaner can be added to the infeed end to wash out bottles

- Cleaner utilizes ionized air and is controlled within the touchscreen and works together with the filler

- Modular built-in ends bolt into the main filler conveyor for precise transitions in bottle feeding

- 3A and sanitary upgrades are available

Technical Data Pressure Overflow Fillers

- Conveyor Width: 115mm

- Conveyor Height: 915mm standard, can be varied per specific application

- Conveyor Length: 2440mm

- Overall Machine Height: 2135mm

- Overall Machine Length: 2550mm

- Overall Machine Weight: 410kg

- Power Requirements: 220V, 10AMP

- Compressed Air: 65 psi @ 3-4 cfm