Description

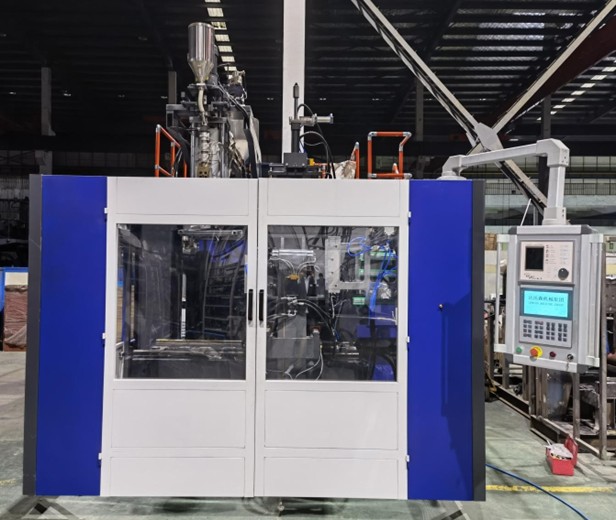

20L HPDE JERRY CAN BLOW MOLDING PROJECT

Suitable For making 10L~ 30L Bottles / Jerry cans

CE approved blow molding machine

COMMERCIAL OFFER:

| Description | Qty | Unit Price | Total Price | |

|

Main machine |

20L jerry can Single station Servo motor Blow molding machine INPB80-30L Average capacity: 55-65 pcs/h

■ Standard Items: 1: TAIWAN-Control Display screen-15’. |

1 |

||

| Mould | 10L Jerry can Mould

1: Single cavity with Sub-mould |

1 | ||

|

Mould |

25L Jerry can Mould

1: Single cavity with Sub-mould |

1 |

|||

| SUBTOTAL | |||||

Auxiliary equipment

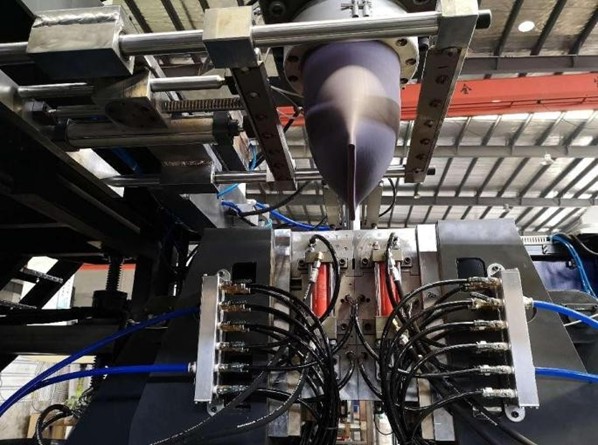

Die head: Continuous type die head

Extrusion system: Top brand automatic temperature controlling device. Drive the screw with electromagnetism motor reducer to realize stepless regulating.

Clamping device: bi-directional synchronous clamping device with double axis single cylinder to stabilize equipment

Blowing device: with upper blowing type

Hydraulic system: The whole hydraulic system adopts world-famous brand controlling components and proportional controlling circles.

Electric controlling system: programmable controller made in B&R Austria. All electric components are world-famous brands

Basic Installation Including – INPB80-30L

Technical Parameters

|

Basic parameters |

Suitable material | PE.PP,PVC,PS,PETG,so on | |

| Max volume | 30L | ||

| Output capacity | 50~60 PCS/H | ||

| Size | 4.8×3.4×3.6(M) | ||

| Weight | 11.3T | ||

| system | Specification | Parameters | Note |

|

Plasticizion system |

|

||

| Summarize | High efficient low power consumption plasticizion system,transducer control,self-protect function when started at low

temperature |

||

| Reducer | Hard finishing、High intension、Low noise reducer | ||

| Screw 1 | ∮80mm,L/D ratio 25,130~160kg/h 38CrMoALA

30kw |

Cooling system available | |

| Heating Zone | 4 Aluminum Heater | Automatic

heating |

|

| Heating power | 15KW/H | ||

| Cooling Fan | Separate cooling system for heaters | Automatic

cooling |

|

Extrusion system |

|

||

| Summarize | High-grade alloy steel, center feeding | ||

| Die head number | 1 | ||

| Center distance of die

heads |

/ | ||

| Max die mouth | 200 | ||

| Extruder Motor | 30kw MOTOR | ||

|

Summarize |

PLC+ touch screen(man-machine interface)standard extrusion blow molding machine controlling system(AUTO monitoring, fault-alarm, auto

counting ,auxiliary function available) |

Taiwan WISETEC H |

|

| Operate interface | Touch screen, automatic self-diagnose alarm system | ||

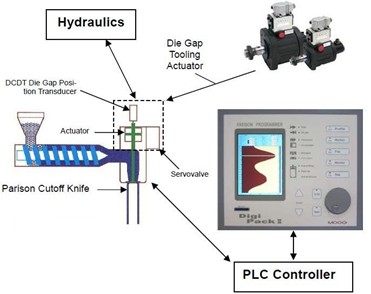

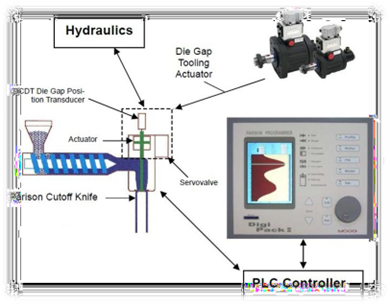

| Parison control | MOOG 100 points controller | ||

| Temperature control | Automatic temperature control module | ||

| Movement control | TECH-2/Mitsubishi, Chinese/English

Version |

||

| Electric protection | Ampere overload, electric short circuit self-

protection function |

||

| TOTAL rated power | 72kw | ||

| Average power

consumption |

40kw | ||

| Inverter | Delta |

|

Hydraulic system |

Summarize | Multiple function hydraulic integrated block Proportional

control, high efficient |

|

| Oil pump motor | 11kw motor (380V/220V,50/60HZ) | ||

| Oil pump | double vane pump | ||

| Valves | Imported oil pump valves and connections

YUKEN |

||

| Oil pipes | Double layer overpressure resistant | ||

| System pressure | LP 100 bar / HP 130 bar

Threads of hydraulic block use of screw joint GE(ISO 1179) |

||

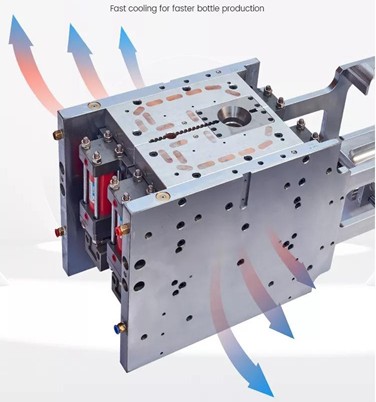

| Cooling system | Post cooling by cooling air and cooling water with

Aluminum Mask |

||

|

Pneumatic system |

Summarize | Taiwan AIRTAC pneumatic system | |

| Air pressure | 0.6~0.8Mpa | ||

| Air displacement | 2.2 M3/min | ||

| Electromagnetic valve | Taiwan AIRTAC | ||

|

Cooling system |

Summarize | Separate cooling system of mould, barrel and oil system | |

| Cooling medium | Water | ||

| Water flow | 100L/min | ||

| Water pressure | 0.4-0.6MPa |

Configuration – INPB80-30L

| Electronic Parts | |

| Name | Trader |

| Parison Control system | Japanese MOOG 100 points |

| Parison Servo valve | Japanese MOOG 100 points |

| Micro computer control system | WISETECH |

| Temperature Controller | WISETECH |

| Auxiliary Relay | OMRON |

| contactor | Schneider |

| Main Power Switch | Schneider |

| Approach switch | Schneider |

| Electric motor | W&N |

| Inverter | INNOVANCE |

| Hydraulic Parts | |

| Oil pump | JAPAN SUMITOMO |

| Valve | JAPAN YUKEN |

| Oil pump and connection | JAPAN YUKEN |

| Sealed part | TAIWAN HALLITE |

| Servo motor | INNOVANCE |

| Servo motor controller | INNOVANCE |

| Air Control System | |

| Cylinder | AIRTAC |

| Air Valve | AIRTAC |

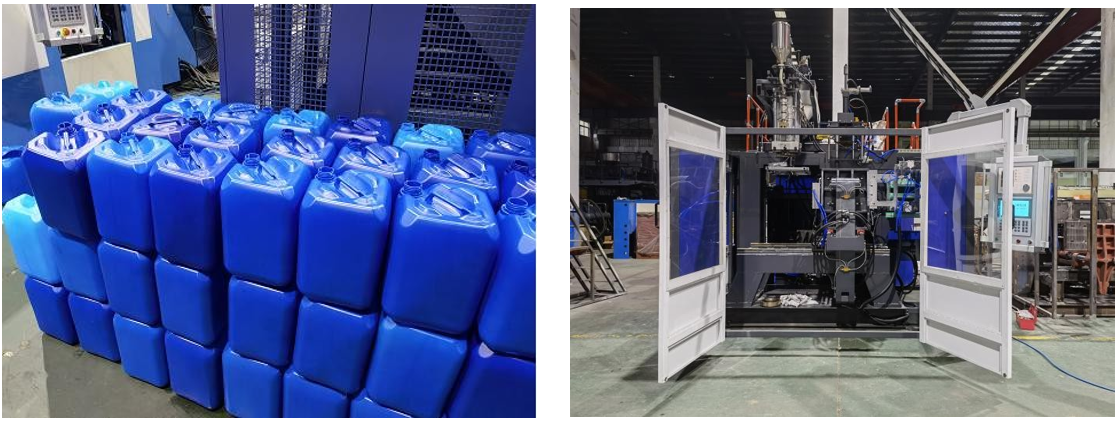

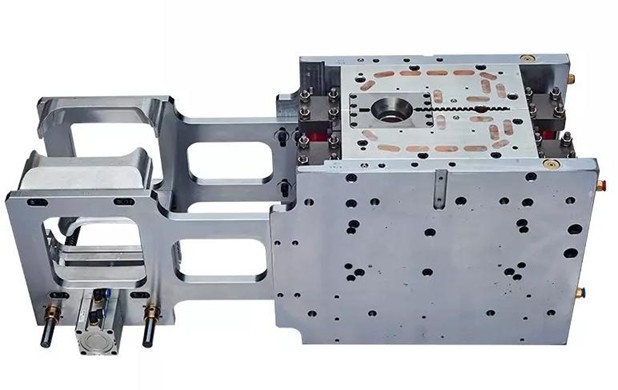

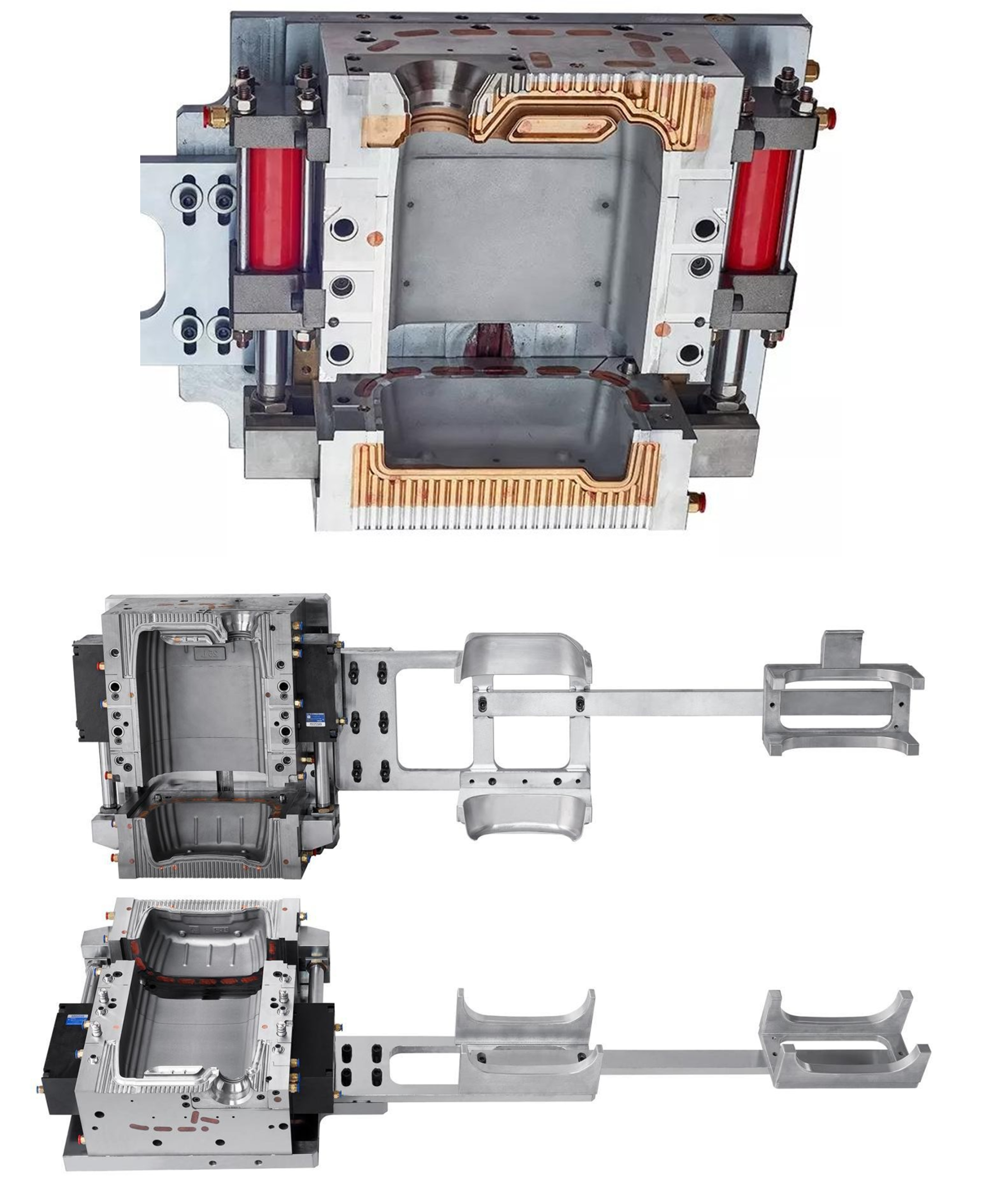

Jerry Can Mould

- Mould material P20# / S136H / Aluminium 7075# with beryllium copper

- mould neck and middle parts are

- Separate cooling system for mould neck, mould body and

- Min 3 million mould

- Optional to make interchangable parts of 20L/25L/30L

- Mould can be made manual deflashing or auto

- Independant cooling system for neck area

- Optional to add inserts to make customer LOGOs or UN LOGOs

- Other jerry cans designs optional for customer to choose

- Jerry can cap mould can also be.

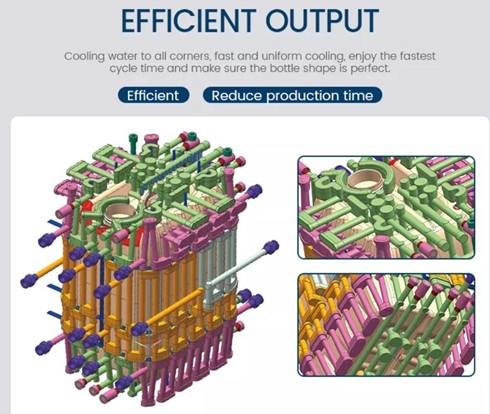

- Our mould cooling water are designed to all corners, this make sure the mould will have

- uniform cooling, to make sure the fast recycle time and perfect jerry can finishing

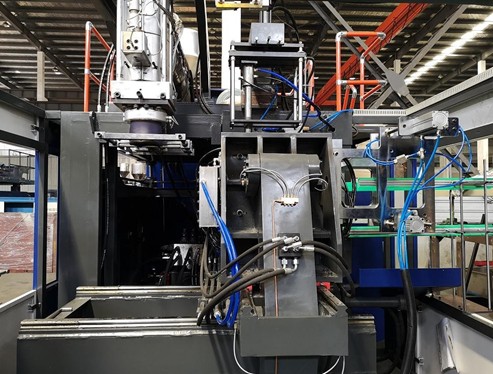

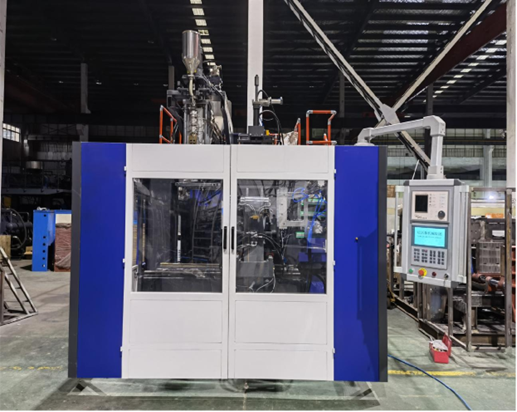

Main Machine

Photos Reference

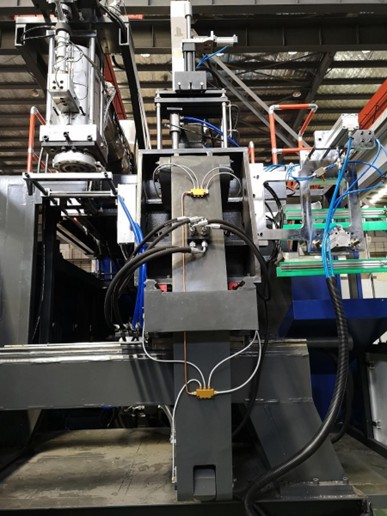

Clamping system

Die head system

Extrusion system

Spare Parts – INPB80-30L

| No | ITEM | QUANTITY |

| 1 | APPROXIMATE SIWTCH | 1 |

| 2 | THERMOCOUPLE | 2 |

| 3 | SOLID RELAY | 1 |

| 4 | MIDDLE RELAY | 1 |

| 5 | AIR SWITCH | 1 |

| 6 | FUSE | 3 |

| 7 | SPEED CONTROLER FOR CUTTER | 1 |

| 8 | DIE CONTROLLER | 1 |

| 9 | SPEED CONTROLER FOR EXTRUDER | 1 |

| 10 | SEALINGS FOR CARRIAGE CYLINDER | 1set |

| 11 | SEALINGS FOR CLAMPING CYLINDER | 1set |

| 12 | SELINGS FOR BLOW PIN CYLINDER | 1set |

| 13 | SEALING FOR BASE UP CYLINDER | 1set |

| 14 | CUTTER WIRE | 2 |

| 15 | CUTTER BLADE | 5 |

| 16 | INSTRUCTION MANUAL | 1 |

Reviews

There are no reviews yet.