Description

REFERENCE: AUTOMATIC 25KG BAGGING MACHINE

The quotation is drafted on the base on the Inpakt Group standards and is not binding. It is subject to firm confirmation upon evaluation of all the technical aspects of the project (sample of product, sample of bags, available space, technical specifications, special request, etc….).

TECHNICAL ASSISTANCE: With 6 specialised technicians available to prevent and solve any problem our machines may have, Inpakt Group provides the following services:

- HOT-LINE: available during office opening hours, the hot line is at the Customers’ disposal to answer any emergency call and to supply the first technical useful information in order to have the plant fixed and properly Though the Hot-Line the Customer will be able to talk with the most suitable technician ready to help him.

- TELESERVICE: thanks to the skill of our staff and the development of new technologies, Inpakt can offer its customers an on-demand supervising and assistance network which allows, via modem, to execute operating diagnostics and any possible updating on the machine control software.

- REGULAR MAINTENANCE: scheduled, precautionary analysis and maintenance on the installed

- SPARE PARTS: Inpakt can quickly supply both the original spare parts and/or tested and pre-assembled pieces of equipment. Thanks to our documentary computerised data-base this service can be also useful for any out-of-production

- INPAKT GROUP CHECK-APP (CUSTOMER HELP CARE KIT) ON ONLY CERTAIN MACHINES, this new digital tool, available for Apple and Android, is the ultimate way to interact with the Inpakt service team, featuring:

- Live chat and video chat with our Hotline

- Instant translator

- Augmented reality for easier fault finding

- Smart Glasses

- FAQ

- Open a Hotline or Spares ticket

- Check the status of your open and closed tickets

- More features to come!

TABLE OF CONTENTS

DESIGN DATA

LAYOUT

EQUIPMENT SPECIFICATION

PRICE SUMMARY

TECHNICAL DATA AND COMPONENTS FOR THE INSTALLATION

MUTUAL RESPONSIBILITY LIST

GENERAL SALES CONDITIONS

To be confirmed with product and bag samples. |

PRODUCT INFO: Spice

PHYSICAL ASPECT / GRANULOMETRY: Different spice variants – To be advised

FLOWABILITY: Free Flowing

BULK DENSITY: 0.35 – 0.65 g/cm³

MOISTURE CONTENT: 5–12%

OIL CONTENT:

PRODUCT TEMPERATURE AT BAGGING: Ambient °C

INFORMATION ABOUT BIG BAG:

DESIGN CAPACITY: 500~650 bags/ hour

Depending on product flow and settling characteristics, bulk density, climatic conditions, humidity level in the work environment, operator speed.

CONTACT PARTS: Stainless steel AISI 316

BIG BAG TYPE / BAG MATERIAL: Woven Polypropylene (PP) Bags

WEIGHMENT OF: 25㎏ and 50kg/bag

DIMENSIONS: To be advised.

LOOPS LENGHT:

BIG BAG CLOSING: Stitched

INFORMATION ABOUT PALLETS:

PALLET DIMENSIONS & MATERIAL: To be advised.

GENERAL INFORMATION:

OPERATIONAL SYSTEM: 5 days/week – 8 hrs./day – 220 days/year

GENERAL ENVIRONMENTAL CONDITIONS:

- Temperature: Ambient

- Humidity: 65% to 71%

The missing data (To be advised) shall be advised within 30 days after the acceptance of this offer.

We would like to advise this quotation based on a standard plant that has NOT been conceived to operate in a potentially explosive environment/atmosphere both internal (i.e. relative to the working process of the equipment) and external. The machines which this quotation refers to are to be placed in non-classified areas (internal or external).

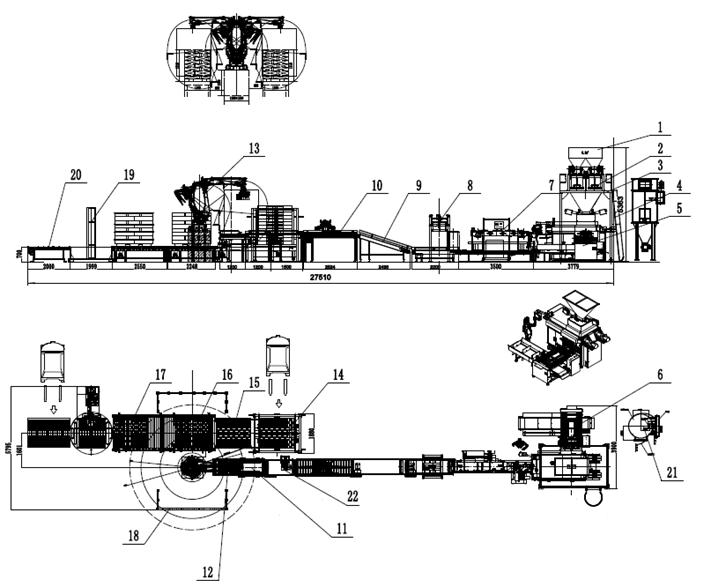

LAYOUT

The Offer / Order confirmation includes the Layout drawing which is attached hereto, or else/and supplied as a separate digital copy (e.g., dwg, pdf file or equivalent).

The Layout indicates, without limitations:

- the Machine’s volumes as positioned on the Customer’s site and its relation to the objects, structures, machines, equipment, etc., existing on the Customer’s site

- utility consumptions

- the position of the connection points with the Customer’s dedusting system

- the operator’s access point

- the position of the Human-Machine Interface (HMI)

- the delivery point for packaging materials (e.g., empty bags) and finished packaged

The Layout is supplied in bi-dimensional version (“2D”). Any tri-dimensional representation (“3D”) of the Machine’s Layout shall not represent an official technical document and shall have a merely indicative visual character.

The Layout is drawn by Inpakt Group further to the information provided by the Customer. By signing this contract, the Customer acknowledges and agrees that the drawing is correct and that the Machine does not interfere with any object or activity carried out on the Site.

In case of changes in the conditions of the site, which may lead to changes in the conformation or installation of the Machine, the Customer will be responsible for the relative costs, and Inpakt will not be responsible for delays or higher costs for the changes and for the different Installation of the Machine, that shall be borne by the Customer.

- 5 m³ Hopper

- Dual weighing packing machine

- Steel support platform

- Safety ladder

- Automatic bag placing machine

- Bag supply

- Sewing machine

- Bag turning machine

- Climbing conveyor

- Bag compressing & reshaping machine

- Transition conveyor

- Robot gripping conveyor

- ABB Palletising Robot 460

- Pallet dispenser

- Empty pallet conveyor

- Palletizing conveyor

- Transition conveyor

- Safety fence

- Online pallet wrapping machine

- Pallet conveyor

- Dust collector

- Auto labeller

EQUIPMENT SPECIFICATION

– Sec. “A” – AUTOMATIC GROSS WEIGHING AND FILLING INSTALLATION FOR BIG-BAGS, MOD. “GROSS-B/G”.

This proposal presents the completed automatic packing machine engineered for packaging capacities ranging from 25 kg to 50 kg. It details all essential parameters of the machine and its auxiliary systems, including functional design, manufacturing standards, structural configuration, and performance capabilities.

The specifications provided represent the minimum technical requirements. Finalized technical details have not yet been established, enabling customers to submit their specific technical preferences or requirements for integration.

For components falling within the defined design scope, the buyer may opt to procure these items independently, provided that all selected parts comply with the required technical and quality standards.

DESIGN & OPERATIONAL CONDITIONS

- Project Name: Fully Automatic Bagging and Palletizing Line

- Quantity: 1 Line

- Installation Location: Indoor

- Operation Mode: Fully automatic, continuous operation

Specifications:

- Material: Spice

- Specific Gravity: 1.2 – 1.3 kg/dm³

- Packing Range: 25 kg and 50 kg per bag

- Packing Speed: 500 – 650 bags per hour

- Filling Accuracy: ±0.2 – 0.5%

- Normal Input Temperature: 30 °C

- Operating Temperature Range: -10 °C to 40 °C

- Bag Type: Plastic bag, 150 microns thickness

TECHNICAL PARAMETERS

| Packing Range | 25kg and 50kg |

| Capacity | 500~650 bag / hour |

| Bag Pattern | Open mouth bag

25kg: empty bag: 400*650mm; filled bag: (В) 380*(А)580*150mm 50kg: empty bag: 400*800mm; filled bag: (В)380* (А)780*150mm |

| Bag Closing Way | Heat sealing |

| Machine material | Stainless steel 304 for contact surface; other parts made of carbon steel |

| Air Source | 0.55~0.65Mpa |

| Gas Consumption | ~130 Nm3/h |

| Power | 13~18KW |

Commercial Offer – Fully Automatic Bagging & Palletizing Line

- Bagging & Filling Equipment

| No. | Item | Description | Unit Price (USD) | Qty | Total Price (ZAR) |

| 1 | 0.5 m³ Hopper | Stainless Steel 316 | |||

| 2 | LCS-Y2 Weighing Bagging Machine | Stainless Steel 316 for

product contact surfaces |

|||

| 3 | Bag-Supplying System | Carbon Steel | |||

| 4 | Bag Placing System | Carbon Steel | |||

| 5 | Bag Clamping & Reshaping System | Carbon Steel | |||

| 6 | Automatic Sewing Machine | Carbon Steel | |||

| TOTAL: | |||||

| 7 | Bag Overturn Machine | Carbon Steel | 1 | ||

| 8 | Bag Climbing Conveyor | Carbon Steel | 1 | ||

| 9 | Bag Flattening and Reshaping Machine | Carbon Steel | 1 | ||

| 10 | Automatic Labelling Machine with Conveyor | Carbon Steel | 1 | ||

| TOTAL: | |||||

- Conveyors & Material Handling

| No. | Item | Description | Unit Price | Qty | Total Price |

| 11 | Transition Conveyor | Carbon Steel | 1 | ||

| 12 | Gripping Conveyor | Carbon Steel | 1 | ||

| 13 | Pallet Conveyor | Carbon Steel | 3 | ||

| TOTAL: | |||||

- Robotics & Automation

| No. | Item | Description | Unit Price | Qty | Total Price |

| 14 | ABB Palletizing Robot (ABB 460) | Single station, with base and gripper | 1 | ||

| 15 | Pallet Dispenser | Carbon Steel | 1 | ||

| 16 | Online Pallet Wrapping Machine | Carbon Steel | 1 | ||

| 17 | Whole Line Control System | PLC: Siemens S7-200 Series | 1 | ||

| TOTAL: | |||||

- Support Structures & Safety

| No. | Item | Description | Unit Price | Qty | Total Price |

| 18 | Support Platform and Ladder | Carbon Steel | 78660 | 1 | |

| 19 | Safety Fence | Carbon Steel | 41040 | 1 | |

- Auxiliary Equipment

| No. | Item | Description | Unit Price | Qty | Total Price |

| 20 | Pulse Dust Collector

(for packing machine only) |

Stainless Steel 304 | 232560 | 1 | |

| TOTAL: | |||||

- Services

| No. | Item | Total Price | ||

| 21 | Project Management, Operations, Start up, Commissioning & Training | |||

| 22 | Delivery in Gauteng included | |||

| 23 | tüv rheinland 3rd party inspection services | |||

| TOTAL: | ||||

MACHINE DETAILS

WEIGHING BAGGING MACHINE WITH STEEL PLATFORM

Reference picture only

The Weighing & Filling Machine is equipped with SUNCELL (USA) load sensors and features 316 stainless steel contact parts, polished to over 200 mesh to ensure hygiene and smooth material flow.

Key Technical Features:

- Power-Off Data Protection: System memory retains all weighing data during power interruptions.

- Automatic Zeroing: Supports start-up zero clearing, cyclical zero clearing, and continuous zero maintenance.

- Automatic Error Detection & Alarm Functions:

- Out-of-tolerance alarm

- Overweight alarm

- Underweight alarm

- Zero position error alarm

- Low material level alarm

- High material level alarm

- Alarm Output Signals:

- Overweight indication

- Underweight indication

- Zero position overweight indication

- Zero position error indication

- Sensor Accuracy Enhancements: Load sensors include temperature compensation and automatic weight correction, continuously adjusting for environmental or operational variations to maintain precise weighing within the configured setpoints.

BAG SUPPLYING SYSTEM

Reference picture only

Main Features

- Vacuum Bag-Suction & Manual Bag-Placement Mode

- Bag-Stock Shortage Alarm

- Low Compressed-Air Pressure Alarm

- Bag-Placement Detection with Integrated Bag-Blowing Function

- Product-Contact Parts Constructed from 304 Stainless Steel, Polished to 300# (customizable per customer requirements)

System Highlights

- Dual Robotic Bag-Placing Arms:

Engineered with a bionic structural design and protected by patented technology, the twin robotic arms accommodate a wide range of bag types and sizes. - Streamlined Five-Step Bag Placement Cycle:

The automatic bag-placing system completes the entire process in only five steps. Its simplified mechanical structure enhances operational convenience and significantly reduces maintenance workload and service downtime. - Precision Servo-Driven Motion:

Movements of the robotic arms are powered by a combination of servo motors and pneumatic cylinders, ensuring precise positioning. Servo angle adjustments allow optimal coordination between the bag-placing mechanism and the automatic bag-clamping unit. - Bag-Mouth Positioning Technology:

Bag alignment is performed at the bag mouth, not the bag bottom as seen in other systems. This eliminates the requirement for strict bag dimensional consistency and reduces overall packaging material cost for the end user. - High-Performance Vacuum System:

World-class vacuum pump technology is used for both bag pickup and bag opening, ensuring stable, consistent vacuum energy to support continuous automatic operation. - Safety Protection System:

Equipped with safety rails and warning indicators to ensure operator protection and safe machine operation.

BAG PLACING MACHINE

The system operates using a two-position automatic switching mechanism, driven by an electric motor to perform continuous bag feeding and bag removal functions. The horizontally aligned bag magazine holds up to 200 empty bags at a time (capacity varies with bag thickness).

Key Features

- Continuous Bag Supply Without Interruption

When one stack of bags is depleted, the system automatically advances the second stack into the bag-pickup position, ensuring uninterrupted operation.- A warning alarm is activated when bag levels are low.

- If both stacks are exhausted, the entire packaging line automatically stops to prevent misfeeds.

- Dust-Proof Pneumatic Component Design

Precision pneumatic components (including solenoid valves) are fully enclosed to prevent exposure, making the system ideal for dusty or particulate-heavy environments and extending component lifespan. - High-Quality Component Selection

All cylinders, solenoid valves, and PLCs are sourced from reputable international brands, ensuring high reliability, accuracy, and long service life. - Closed-Contact Bag Detection

Bag presence is verified using a fully enclosed contact-based detection method, rather than the vacuum detection systems used in other models.

This design significantly reduces material loss and prevents scattering caused by unclamped or misaligned bags. - Enhanced Operational Safety

- Non-conforming or unqualified bags are automatically ejected externally without stopping the machine.

- The operator is never exposed to unsafe conditions during bag removal.

- A safety mesh guard and warning system provide additional protective measures.

- Bag Feeding Capacity

Capable of supplying 500–650 bags per hour, supporting medium to high-speed packaging lines.

BAG CLAMPING & RESHAPING MACHINE

- The unit ensures that each bag is properly aligned and maintained in its correct shape before entering the bag-closing system. Height adjustment is fully configurable, and conveying speed is controlled through variable-frequency (VFD) regulation for smooth, stepless speed adjustment.

- Drive System:

Alternating current motor, 380V ±10%, 50Hz - Motor Power:

37 kW - Equipped with a safety mesh protection and warning system to ensure safe and reliable operation.

BAG SEWING MACHINE

Picture for reference only

Technical Parameters:

Sewing machine. automatic cutting thread, 0.37kw, Single needle, two threads

Start-stop: automatically by photoelectric switch

Thread chain cutter: automatically by air cylinder operated guillotine cutter

Stitch length: 7-10.5mm, adjustable (generally, 10mmm)

Standard needle: 80800 x 200-250#

Seam: Double Thread Chain Stitch (Type 401)

Speed adjustable

thread: 20*6 nylon thread, 30/4*3 cotton thread, or similar ones, etc.

lube oil system

Tape folder: adjustable for 50-70 mm wide tape (selected with additional cost)

500*500*325mm, 36Kg, Carton package

BAG OVERTURN MACHINE

The roller guide and pushing mechanism reorient the filled packaging bags into the correct horizontal alignment with the conveyor belt. Once aligned, the system simultaneously transfers the bags forward along the conveyor for continuous downstream processing.

Technical parameter:

Form: Flat belt type

Conveyor belt material: rubber belt

Conveyor length: 2000mm~

Belt width: ~600mm

Conveyor height: ~600mm

Machine material: carbon steel

BAG FLATTENING AND RESHAPING MACHINE

The conveyor is equipped with a roller guide plate and an integrated bag-pressing device, which reorient filled bags into proper horizontal alignment with the conveyor belt while simultaneously flattening and levelling the bag shape for smooth downstream transfer

Technical Specifications

Conveying Length: Approximately 2500 mm

Conveying Speed: 8–12 m/min

Conveyor Belt Width: Approximately 600 mm

Motor Power: 0.75 kW

AUTOMATIC LABELLING MACHINE

This labelling machine is custom engineered according to customer production requirements to achieve precise online product labelling.

The labelling position is adjustable within a specified range to accommodate varying production needs.

Applicable Industries:

Food, medical, cosmetics, electronics, plastics, toys, hardware, automotive parts, stationery, and other manufacturing sectors.

Functionality

- Enhances labelling and film application efficiency, ensuring accurate placement, high quality, and operational stability.

- Eliminates issues associated with manual labelling, such as low efficiency, skewed or wrinkled labels, blistering, and inconsistent placement.

- Reduces product costs, improves logo aesthetics, and enhances overall product competitiveness.

- Supports online printing of production dates and batch numbers.

Key Advantages

- Stable PLC Control System:

- Ensures high-speed, consistent operation.

- Attachment and labelling are precise, reliable, and stable.

- Simplified adjustment mechanisms for easy operation.

- Touch Screen Operation:

- User-friendly interface for practical and efficient control.

- Three-Dimensional Labelling Station:

- Upgraded 3D angle adjustment allows accurate labelling of conical or irregularly shaped bottles.

Operation Process

- Load products

- Automatic product delivery

- Automatic labelling

- Collection of labelled products

Supports online integration or stand-alone operation.

Fully customizable input/output direction: right-in/left-out or left-in/right-out.

Technical Parameters

- Labelling Accuracy: ±1 mm (excluding product and label tolerances)

- Labelling Speed: Up to 17 pieces/min (depending on product and label size)

- Applicable Label Size: 58 × 38 mm

- Product Size: Customizable based on customer specifications

- Power Supply: 220 V, 50/60 Hz, 2.0 kW

- Machine Dimensions: Customized according to customer requirements

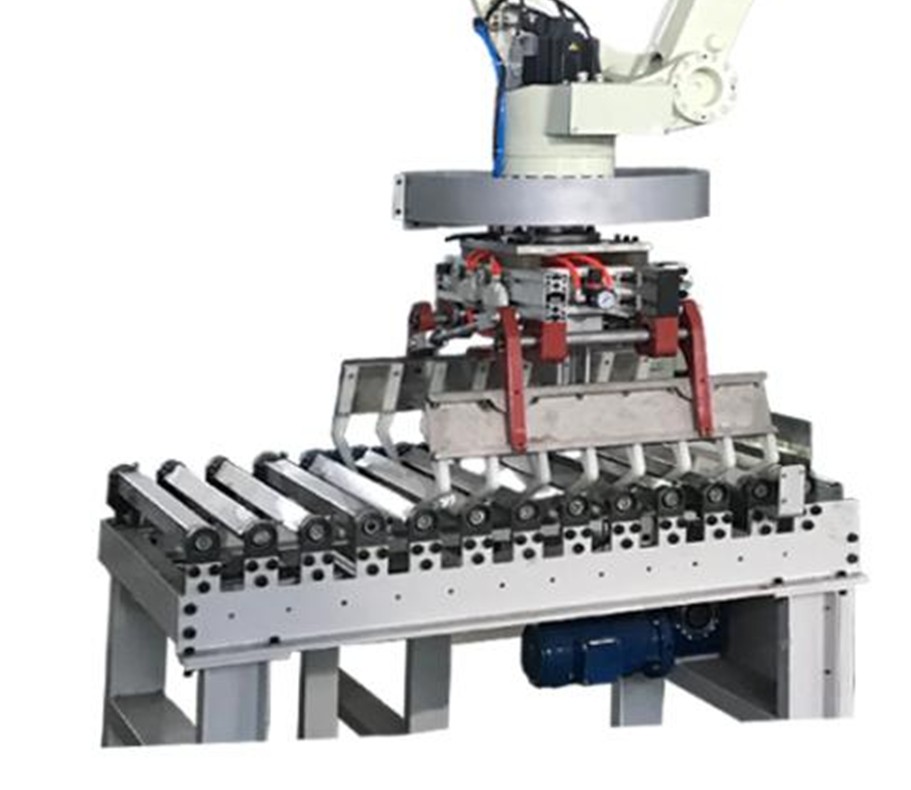

GRIPPING CONVEYOR

Technical Specifications

- Conveyor Length: 1,200 mm

- Conveying Speed: 12 m/min

- Roller Diameter: 700 mm

- Conveyor Height: Adjustable, 400–500 mm

- Power Supply:75 kW, 3-phase, 240 V, 50 Hz

ABB PALLETIZING ROBOT

The main unit of the manipulator utilizes an palletizing robot. It features a compact footprint, simple operation, low energy consumption, and easy maintenance, with touch-screen interface for convenient control.

Main Features

- Throughput: 300–800 bags/hour, configurable with single or double palletizing stations; palletizing performed at the mechanical hand position.

- Construction: Aluminium alloy and FRP shell for a lightweight, low-noise design. Efficient power usage minimizes energy consumption.

- Design Benefits: Compact, lightweight, fast, safe, energy-efficient, and aesthetically designed. Reduces production line length, equipment count, and simplifies workflow.

- Servo Motors: Fully enclosed, self-cooling type for reliable performance.

- Stacking Configuration: 2×3 bag grouping, 5 bags per layer, 8 layers per stack.

- Safety: Equipped with safety mesh and warning system for secure operation.

Technical Parameters

- Mechanical Structure: Multi-joint robot

- Motion Type: Cylindrical coordinate system

- Axes: Standard four-axis configuration

- Gripper Type: Finger-type

- Palletizing Memory: Standard 30 programs, expandable up to 400

- Teaching Methods: Manual teaching, supported teaching, or teaching exemption

- Maximum Pallet Height: 2,300 mm

- Maximum Palletizing Width: 1,500 mm

- Rotation Angles: θ (turn) and α (wrist) both 330°

- Power Supply:5 kVA, 200 V, 3-phase, 50 Hz

- Compressed Air Requirement:5 MPa

- Floor Area Required: 2,000 mm × 4,000 mm

- Equipment Weight: 1,150 kg

- Gripper Payload Capacity: 25–50 kg per bag

PALLET DISPENSING UNIT

The pallet handling system is designed to ensure accurate, stable, and timely delivery of empty and full pallets through coordinated pneumatic and conveyor mechanisms.

Key Functions

- Empty Pallet Handling:

- Utilizes two coordinated pneumatic devices to release empty pallets with precision.

- The empty pallets are transferred to the pallet conveyor in a controlled and stable manner.

- The pallet warehouse can accommodate 8–10 pallets.

- When only two pallets remain and replenishment is overdue, an alarm is triggered, and the system automatically stops until pallets are replenished.

- Pallet Conveyor:

- Transports empty pallets from the pallet warehouse to the palletizing conveyor

- Palletizing Conveyor:

- Receives filled packages from the roller conveyor and arranges them for palletizing according to the configured stacking plan.

- Full Stack Conveyor:

- Temporarily stores fully stacked pallets transported from the palletizing conveyor or roller conveyor before transferring to the next stage.

- Fork Conveyor:

- Holds fully stacked pallets temporarily and facilitates smooth transfer via forklift to the warehouse or storage area.

ONLINE PALLET WRAPPING MACHINE

Picture for refence only

The automatic wrapping machine is widely applicable across industries including glass, paper, chemicals, building materials, textiles, beverages, electronics, food, and pharmaceuticals. It provides efficient and stable pallet wrapping for a wide range of product sizes and weights.

Technical Specifications

- Turntable Diameter: 1,650 mm (customizable per pallet size)

- Maximum Packaging Height: 2,000 mm

- Machine Height: 2,400 mm

- Turntable Height: 85 mm

- Maximum Load Capacity: 2,000 kg

- Machine Weight: 700 kg

- Power Supply:55 kW, 3-phase, 240 V, 50 Hz

- Turntable Speed: 0–12 rpm, variable

Main Performance Features

- Control System

- PLC programmable control; allows adjustment of winding layers and cycle counts.

- Photoelectric sensing automatically detects pallet height.

- Localized reinforcement function allows special protection for specific areas of the load.

- Cycle time setting for precise wrapping sequences.

- Turntable Drive

- Variable-frequency drive with adjustable speed from 0–12 rpm.

- Automatic turntable reset after each cycle.

- Film Handling System

- Film pre-stretch up to 250% for efficient usage.

- Adjustable film tension, feed speed, rise/fall speed to suit different loads.

- Independent adjustment of top and bottom wrap layers.

- Film carriage system designed for smooth, reliable operation.

- Column & Lifting Mechanism

- Double-chain drive ensures stable and precise vertical movement of the film carriage.

- Maximum wrapping height is customisable to match pallet requirements.

PULSE DUST COLLECTOR

Picture for reference only

Introduction

The pulse dust collector is designed to efficiently separate dust and particulate matter from the airflow in packing operations. Its structure is divided into upper, middle, and lower sections:

- Upper Section:

- Equipped with multiple injection pipes, each containing several injection holes connected to the top of the filter bags.

- Solenoid valves are connected to an external high-pressure gas storage tank to provide pulse cleaning.

- Middle Section (Dust Filter Box):

- Contains venturi-mounted skeletons covered with cylindrical filter cloths made from various materials.

- Dust-laden air enters the filter box, where sudden expansion reduces wind speed, causing part of the dust to settle into the ash hopper. Remaining dust-laden air passes through the filter bags, allowing gas to exit while trapping dust outside the bags.

- Lower Section:

- Composed of a 70° conical ash hopper.

- Equipped with an anti-blocking airlock to discharge collected dust, which can often be recycled as product.

Working Principle:

- Dust-laden air enters the collector and flows through the filter bags. Dust accumulates outside the filter media, separating gas and particulate matter.

- Periodically, pulse solenoid valves release compressed air through injection pipes and venturis to expand the filter bags instantly, generating reverse airflow to clean the dust off the bag surfaces.

- The dust falls into the cone and is discharged via the airlock, maintaining continuous filtration and high efficiency.

Technical Parameters

| Number of Filter Bags | 24 | ||

| Filter Bag Size (mm) | 120 × 1,600 | ||

| Air Volume (m³/h) | 3,220–4,260 | ||

| Pressure (mmH₂O) | >120 | ||

| Filter Area (m²) | 16–19 | ||

| Blower Power (kW) | 2.2 | ||

| Discharge Motor (kW) | 0.55 | ||

| Filter Speed (m/min) | 3–4 | ||

| Filter Pressure (Pa) | -1,960 to +2,940 | ||

| Compressed Air Consumption (m³/min) | 0.12 | ||

| Filtration Efficiency (%) | >99 | ||

| Noise Level (dB(A)) | <75 | ||

| Weight (kg) | 940 | ||

| Material | Stainless Steel 304 |

DOCUMENTATION SUPPLIED WITH THE MACHINES IN COMPLIANCE

Inpakt Group; machines only

| DOCUMENT | LANGUAGE | DELIVERY FORMAT | |

| PROJECT COMMUNICATIONS | ENG | ||

| INSTRUCTION MANUAL*

comprising: – Machine descriptions – Function and Operation description – Machine maintenance |

(language of the destination country) |

PDF + HARD COPY |

|

| OPERATOR MANUAL COMPRISING:

– User instruction for operator panel interface – Alarm list with description |

(language of the destination country) |

PDF + HARD COPY |

|

| LIST OF RECOMMENDED SPARE PARTS** | (language of the destination country) | XLSX | |

| COMPLETE ONLINE SPARE PARTS LIST

Personalised access to dedicated online spare parts portal via user ID and password. 2D and 3D exploded views to identify required and recommended spare parts. Possibility of sending an offer request directly to the after- sales department. |

ITA+ENG |

WEB APP |

|

| ELECTRICAL/ELECTRONIC DIAGRAMS | ITA + (ENG + FRE + GER +SPA)

only one of these |

PDF + HARD COPY | |

| PNEUMATIC DIAGRAMS | ENG + FRE + ITA + GER + SPA | PDF + HARD COPY | |

| TECHNICAL DOCUMENTATION OF THE MATERIALS SUPPLIED BY OTHER COMPANIES

(PLC, weighing systems, gear drives, pneumatic materials etc.) |

ENG |

|

|

|

LABELS AND SIGNALS |

Safety labels and signals | (language of the destination country) | |

| Regulation labels and signals | (language of the destination country) | ||

| HMI PANEL | (language of the destination country) | ||

* The definitive version of the instruction manuals will be supplied within 25 days after the signing of the acceptance test.

** The list of spare parts and exploded drawings will be supplied within 30 days after the final installation test. Should they be requested before the delivery to site, they will be prepared and submitted in a temporary and budgetary format.

All rights of reproduction, distribution, electronic files, total or partial adaptation by any channel toward third party is forbidden without written authorization by Inpakt Group.

TECHNICAL DATA AND COMPONENTS FOR THE INSTALLATION

| Power supply voltage: | 380 V – 50 Hz + N + PE |

| Distribution system | TN-S |

| Command voltage: | 24 Vdc |

| Installed electrical power: | to be defined |

| Degree of electrical protection: | IP55 |

| Minimum pressure for compressed air supply: | 6 bar (minimum) |

| Compressed air consumption: | to be defined |

| Operating temperature: | 5°C to +40°C |

PNEUMATIC COMPONENTS

| Air valves: | INPAKT STANDARD |

| Air cylinders: | INPAKT STANDARD |

| Pneumatic fittings: | INPAKT STANDARD |

| Filter: | FESTO |

ELECTRIC COMPONENTS

| Loading sensors | SUNCELL, USA |

| Weighing Indicator | ANC-501 |

| Electromagnetic valve | AIRTAC |

| Pneumatic cylinders | AIRTAC |

| Oil-water separater | AIRTAC |

| PLC | SIEMENS S7 |

| Touch screen | SIEMENS |

| Invertor | TAIDA |

| Electric elements | SCHNEIDER |

| Buttons | SCHNEIDER |

| Level sensors | SIPAI |

| Motor and Servo Motor | SIEMENS |

| Vacuum pump | HAOLIWANG |

COLOUR OF CONDUCTORS INSIDE ELECTRICAL PANEL

| 400 V = | black at least 1.5 mm |

| 230 V = | black at least 1.5 mm |

| Neutral = | blue at least 1.5 mm |

| Earthing = | green/yellow 2.5/16 mm |

| +24Vcc = | red 0.5/1 mm |

| 0 Vcc = | blue 0.5/1 mm |

| Connections = | white 0.5/1 mm |

COLOUR OF PUSH-BUTTONS

| RED = | Emergency |

| YELLOW = | Abnormal conditions |

| GREEN = | Start |

| BLUE = | Activate under obligatory condition |

| WHITE, BLACK = | Various functions |

SIGNAL-LIGHT COLOURS

| RED = | Emergency |

| YELLOW = | Abnormal conditions |

| GREEN = | Start |

| BLUE = | Require worker intervention |

| WHITE = | Various general function |

MACHINE-SIDE CONNECTIONS

The cables from the panel to the machinery are placed inside metal trunking. From the trunking exit directly to the machinery, the cables are placed in piping or tubing with open curves, so that in certain points, the cables are unprotected.

PUSH-BUTTON CONTROL PANELS

The push-button control panels will be positioned in one place on each machine. This position will be determined by Inpakt based on the installation requirements of the machinery.

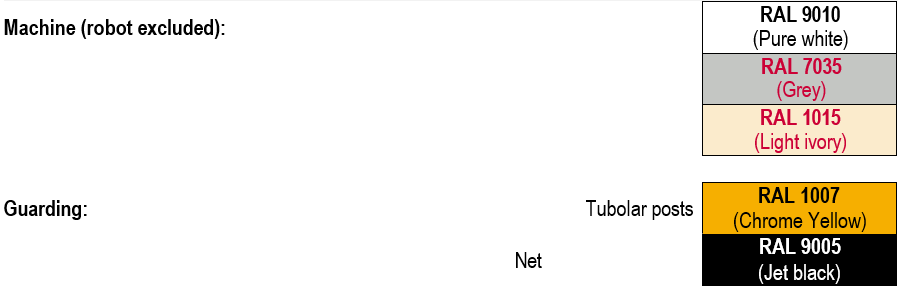

PAINTING

– Standard

Machine:

– SA 2 Sandblasting

– Painted

STANDARD COLOURS

Upon request, alternative colours can be quoted separately

SOFTWARE PASSWORDS AND SOURCE CODES DISCLAIMER

Inpakt does not provide and is not obliged to provide, grant in use, license or allow the Customer access to the password(s) of the Machine’s software system, except for any programmable feature necessary to allow the normal use of the machine, based on its intended use.

Likewise, Inpakt does not provide and is not obliged to provide, grant in use, license or allow Customer access to the source codes of the software system installed on the Machine.

The data reported in this technical specification is to be considered as purely indicative and they may undergo some variations once the project has been defined. Inpakt reserves the right to modify the Technical Data and Components for the Installation with equivalent brands based on the current availability on the market.

MUTUAL RESPONSIBILITY LIST

The following list describes the general obligations and responsibility of the Parties with respect to the activities required to produce and deliver the Machine. The specific terms and conditions of these mutual responsibilities are further specified in this Agreement. Every modification of the list in this Section must be agreed to in writing by the Parties. Where the list provides a Price upcharge, the related Price must be agreed to by the Parties

| DESCRIPTION | RESPONSIBILITY | |

| Factory Acceptance Test | Inpakt | Customer |

| Shipment of products and packaging materials, including without limitation, bags, pallets, products etc., in the quantity required by Inpakt, at the required time | X | |

| DDP Bastia Umbra shipment of such products and materials for the FAT | X | |

| Applicable safety documentation for such products and materials | X | |

| Disposal of such products and materials (if applicable) | X | |

| Cost of disposal of such products | X | |

| Building | Inpakt | Customer |

| Any civil engineering and works for Machine Installation | X | |

| Cranes and lifting rails for all assembly and maintenance work | X | |

| Pipe and cable racks, footbridges, stairs and platforms | X | |

| Heating, air conditioning system, grounding and lightning | X | |

| Verify that all the passageways (doors, etc.) for reaching the installation place are of suitable size, and that any structures are capable of supporting the load of machines and lifting equipment. |

X |

|

| Distribution of energy and fluids | Inpakt | Customer |

| Compressed air and chilled water (if applicable) | X | |

| Electric energy supply and connections to the take-over points | X | |

| Power feeding cables from the plant main distribution panel to the supplied equipment take-over points | X | |

| Internal wiring of Machine and equipment | X | |

| Training and documentation | Inpakt | Customer |

| Destination country related certifications, unless otherwise specified | X | |

| Manual | ||

| One set (on a paper materials) | x | |

| Installation, Commissioning and Site Acceptance Test | Inpakt | Customer |

| Unloading and unpacking of the Machine | ||

| Custom clearance | X | |

| Unloading and positioning of the Machine in the Site | X | |

| Unloading insurance policy | X | |

| Crates unloading and opening (unpacking) | X | X |

| Positioning of the Machine and relevant safety guards | X | |

| Lifting/hoisting equipment available with driver, for unloading the material and placing it in its final assembly position (fork-lift truck with capacity of 7 tons and/or crane, to be established based on requirements). |

X |

|

| Any necessary equipment to enable the Inpakt technicians to the overhead – works, according to safety regulations in force, i.e. fixed or mobile stairs, ladders, platform, scaffolding, elevators etc.to be established according to requirements. |

X |

|

| Installation, Commissioning and Site Acceptance Test | ||

| Disassembling and/or adaptation of existing machines | X | |

| Operation, monitoring, and control of any devices currently mounted and/or supplied by others, located either upstream or downstream from the Inpakt supply (valves, gates, product feed systems, belt conveyors, elevators, wrapping devices, check-weighers, ink-jets, etc. |

X |

|

| Connection to the product-feeding system. Please note that the connection to the Inpakt-supplied load hopper must be with flexible connection, the product feeding system must not be connected to the structure of the weighing installation, to prevent any vibrations that could interfere with the correct function of the weighing system | X |

|

| Products and operators for Commissioning and Site Acceptance Test | X | |

| Supervision to Installation/assembly operation, tests, Commissioning and Acceptance Test | X | |

| Miscellaneous | ||

| Working permissions for Inpakt’s group personnel on Site (if required) | X |

| Products, consumables and utilities for the installation phase (water, electric power, air,…….) and relevant connections and piping | X | |

| Raw materials losses, product losses, production losses during tests and starting-up | X | |

| Locked room for tooling storage and Inpakt’s personnel changes of clothing | X | |

| Internet connection near the electrical panel where the Teleservice and/or router is present, to allow the Inpakt technicians to test the Machine and the Teleservice | X | |

| Telephone line and fax line available, high speed internet connection and conditioned meeting room | X | |

| Thorough cleanup of the work site and Machine | X | |

| Any additional costs suffered by Inpakt due to exceptional and unpredictable events occurring in the time prior to Shipment or SAT causing unexpected increases of Prices of (without limitations) raw materials, mechanical and electrical components, energy, freight or manpower. Such costs, duly documented, shall be quantified by Inpakt and added to the Sale Price. |

X |

|

| Local Taxes, additional inspections, additional tests and/or any modifications to the Customer’s site which may be required by the local competent bodies for the sake of the Machine’s compliance with the local norms. |

X |

GENERAL SALES CONDITIONS

DELIVERY TIME: To be determined

(210 days after receipt of the down payment, written order and all technical

PACKAGING FOR SEA TRANSPORT AND TRUCK LOADING AT THE INPAKT FACILITY: INCLUDED THE PACKING WILL BE IN CONFORMITY WITH THE RELEVANT INTERNATIONAL STANDARDS

PAYMENT:

- 40 % UPON ORDER

- 50 % UPON NOTIFICATION THAT THE GOODS ARE READY AND BEFORE THE SHIPMENT OF THE MACHINES

- 10 % UPON SUCCESFULL A.T. BUT NOT LATER THAN 40 DAYS AFTER THE PLANT DELIVERY

Payments are due upon receipt of the invoice, at sight. Remittance shall be by wire transfer only.

Should the Customer not require the goods at the date fixed in the contract, whatever the reason, the payment of the 50% of the total amount remains due, against receipt of the invoice by Inpakt.

Should the goods be delivered but the installation cannot be completed, whatever the reason, the payment of the 10% as settlement of the total amount remain due, against receipt of the invoice by Inpakt.

If the Customer fails to pay by the stipulated date, Inpakt shall be entitled to interest from the day on which payment was due and to compensation for recovery costs. The rate of interest shall be as agreed between the parties or otherwise 8 (eight) percentage points above the rate of the main local refinancing facility. The compensation for recovery costs shall be 1 (one) per cent of the amount for which interest for late payment becomes due.

Should the Customer delay any due payment, Inpakt, without prejudice and in addition to any other right, action or remedy provided by law and under this Offer/Order Confirmation, will be entitled to postpone any activity or obligation related to this Offer/Order Confirmation, until such time as the payment has been made by the Customer.

If the Customer has not paid the amount due within one month, Inpakt shall be entitled to terminate the contract by notice in writing to the Customer, retain the down payment and, in addition to the interest and compensation of recovery costs according to this article, to claim compensation for the loss he incurs.

INVOICING and PAYMENTS

Payment of the Purchase Price shall be made by the Customer in the invoice currency and in accordance with the Payment Conditions set out above to the bank account indicated by Inpakt All Parties acknowledge and agree that invoices and bank account details shall be sent exclusively in original documents by one of the following methods:

- mail with evidence of receipt

- courier service with evidence of receipt

- fax

The Customer acknowledges and agrees he will make payments exclusively to the bank whose details are included by Inpakt in one of the methods mentioned above, and that will be responsible for any breach of the provision of this paragraph.

It is understood that payments shall be deemed made to Inpakt at the time when the sum has been unconditionally and irrevocably credited to the bank account effectively owned by Inpakt.

OPERATING BANK

First National Bank

GUARANTEE:

The machinery is guaranteed for a period of 12 (twelve) months (3500 hours max) after the date of acceptance of the equipment by Customer, but in any case, no longer than 18 (eighteen) months from the delivery date of equipment, whichever comes first. The warranty provided by Inpakt for machines manufactured by third parties and included in this contract shall be that of the manufacturer of such machine.

MECHANICAL, ELECTRICAL, PNEUMATIC, ELECTRONIC WARRANTY:

The guarantee consists of the replacement of the parts that are recognized as originally defective. These parts are delivered ex-W our factory, all the replacement cost are at the Customer charge. Their replacement should be carried out by Customer engineers.

The warranty does not include normal wear parts, nor parts damaged by corrosive agents, or any causes unrelated to normal installation operation (blows, lightening, etc…) or by inadequate maintenance or utilization.

All the replaced components must be returned to our technical department to be analysed so the type of damage can be evaluated.

Return shipping of defective components to Inpakt will be at Customer charge.

Inpakt reserve the right to revise the technical and commercial conditions of this offer if, upon the study of the bag and product samples and of the Customers needs, there should be requirements which are different from the ones initially known or taken into consideration in drawing up the offer.

FACTORY ACCEPTANCE TEST

Before the delivery of this supply a pre-final test will be made (or a final test, as per the agreement between the parties) concerning the whole supply or a part of it, at the Inpakt plant.

If, upon the Customers request or in the opinion of Inpakt, this pre-final test should be carried out with all or part of the Customers products which are listed in this offer/order confirmation, then the Customer commits to ship the product/s to our plant according to the requested quality and quantity and equipped with all the documentation necessary to safety and to its identification and classification.

Our technical department will send a formal request specifying the quantity, the necessary documentation, when and how the product is required to arrive at Inpakt

All the costs relevant for the product shipment to Inpakt (e.g. transport charges, customs duty, storage costs, etc…) will be charged to the Customer together with any return shipping charges from our plant to the Customer.

If for reasons of space, customs or letters of credit the material cannot be sent back with the plant, the cost of return shipping will at Customer charge.

If the return of the product is not possible due to circumstances beyond our control or if the Customer clearly states that he doesn’t want the product returning, all disposal costs, supported by the appropriate documentation, will be charged by Inpakt to the Customer.

The Customer commits himself to ship the product correctly so that its chemical, physical and fluency features will be perfectly corresponding to that being fed from the discharge point of the Customer (silos, buffer hopper, etc…).

The quantity of product that is returned could be different (that is lesser) than the quantity shipped, due to product dispersion during the pre-final test. In this case Inpakt will not be obliged to pay any charge nor will it be obliged to refund the equivalent value of this product.

Inpakt reserves the right to cancel the machine pre-final test with a determined product even if it has been already shipped by the Customer, the Customer cannot claim for any charging of material or costs of shipping.

PASSAGE OF TITLE AND RISK OF LOSS AND/OR DAMAGE

Risk of loss or damages of Products shall pass from Inpakt to the Customer on the Delivery Date at the Delivery Point. Inpakt reserves title to the Products until full payment of the Purchase Price; therefore, the Customer shall not resell or dispose of the Products. The Customer undertakes to take all necessary measures to set up a valid reservation of title in its country in the most extensive form permitted and/or to institute a similar form of guarantee in favour of Inpakt; the Customer further undertakes to cooperate with Inpakt to establish those measures required to protect the property rights of Inpakt. Inpakt shall be authorized to take, at the Customer’s expense, all necessary measures to secure reservation of title against third parties.

The retention of title shall not affect the passing of risk under this clause.

FORCE MAJEURE

At approach of force majeure circumstances for fulfilment of the contractual obligations by any of the Parties, namely: fire, flood, earthquake, other Acts of God, acts of civil or military authority, labour disputes, fire, riots, civil commotions, sabotage, war, embargo, blockage, boycotts, floods, epidemics or pandemics, delays in transportation, governmental restrictions, delays in receipt of raw materials for the Machine, or acts or omissions of the other Party (such an occurrence a “Force Majeure Event”), actions of Governmental and Administration bodies and other emergency circumstances that could not been either foreseen by the Parties or prevented by reasonable measures and if these circumstances have directly affected the execution of the present Contract, term of fulfilment of the obligations is extended for the period equal to that one, during which such circumstances will act.

These circumstances shall be valid also if not specifically certified by Commercial Chamber or other competent bodies of the appropriate country of Inpakt, of the Customer or other neutral country.

The Party, for which the impossibility of fulfilment of the contractual obligations was created, should during 20 (twenty) days inform the other Party on approach and termination of such circumstances.

INTELLECTUAL PROPERTY

The Customer acknowledges and agrees that nothing in this offer and/or order confirmation shall be construed or interpreted as granting the Customer with any right or interest in any drawing, document, software, instructions or information concerning the manufacture, assembly, installation or use of the Products (otherwise referred to as “Technical Information”) supplied by Inpakt to the Customer, that is, and shall remain, exclusive property of Inpakt.

Moreover, the Technical Information shall not be exploited by the Customer for extra contractual purposes nor shall they be copied, reproduced, transmitted or made known to third parties without pre-emptive and written permission of Inpakt.

Industrial Property is and shall remain exclusive property of Inpakt and the Customer shall not acquire, by means of the contract, any title, property, right or interest thereof.

VALIDITY OF THIS OFFER 30 DAYS.

Reviews

There are no reviews yet.