Description

JUICE & WATER BOTTLING LINE FOR APPROX. 2000BPH (750ML)

TO FILL FROM 200ML TO 5L BOTTLES / STARTING OFF SEMI AUTO & THEN AUTOMATED.

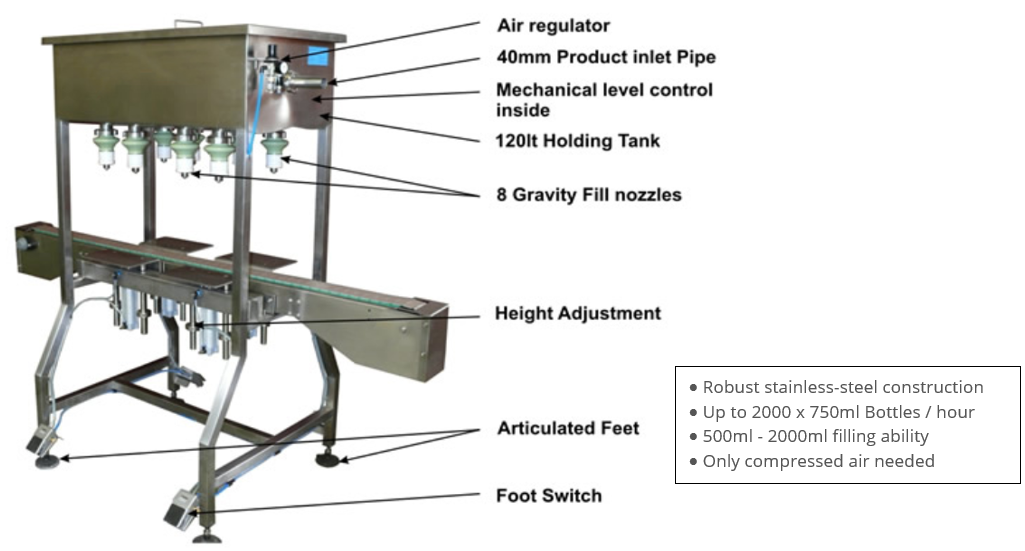

1) 8 head step filler / STT-8PF

- Gravity level Filling principle is used

- Filling speed of up to 2000 bottles per hour on still water in 750ml bottle

- The liquid level in the product hopper is controlled by means of a plastic float valve

- Machine is manufactured entirely from stainless steel

- Lifting filling platforms are lifted by pneumatic cylinder so compressed air is required

- Filling nozzles are actuated by the containers and therefore have a built in no bottle no fill function

- Filling level is adjustable

- The lifting platform is height adjustable for different bottle sizes

- Machine suitable for 200ml-2000ml

2) Automatic Capper with Cap Feed Hopper / CPP-118S

The Semi-Auto Chuck Capper is designed for when specific torque accuracies are needed. The operator of the machine manually places the caps on the bottles as they pass and the Semi-Auto Chuck Capper automatically tightens them. The Semi-Auto Chuck Capper uses the same chucks and inserts as are other cappers to accurately tighten caps. An electronic clutch determines how much torque is applied to each cap. Our Semi-Auto Chuck Capper’s are designed to handle most bottle types including P.E.T, P.V.C, plastic, and glass. To eliminate damage to caps and reduce insert wear, the Semi-Auto Chuck Capper comes with adjustable electronic torque values. A Conveyer and an operator are required. the operator is required to place caps on the bottles as they pass by on the conveyer. Once the caps are placed the Inpaktcapper can then secure them onto the bottles. The Semi-Auto Chuck Capper comes complete with: an A.B.I. unit, a universal stand to mount onto your conveyor one chuck, and one insert.

Specifications

Dimensions:

Length:1524 mm

Length:1524 mm

Depth: 914.4 mm

Height: 609.6 mm

Weight: Approx. 68.03 kg

Capping Speed: Up to 30 CPM*

Cap Size: Min: 10mm / Max: 120mm

Torque Range: 1 – 90 In-Lb

Electrical: 220 V

Air Requirements: 120 PSI @ 2 CFM

3) Self-Adhesive Labelling Machine Filler / LBL 400R

Specifications

- Footprint size 950mm x 890mm wide x 450mm height

- Label Roll 75mm inner diameter; 300mm outer roll diameter

- Power 110v 50/60Hz

- Label head stepper motor

- Emergency safety Off unbutton

- SUS#304 stainless steel and aluminum alloy frame construction

- Automated labelling for up to 85% wrap labels on straight-sided round bottles at speeds of 20-50 bottles per minute

- No adjustments needed: built-in conveyor automatically matches label speed.

- Labelling accuracy ± 1mm

- Individual label height of 12 mm (½ inch) to almost 102 mm (4 inches) tall

- Individual label width of 12 mm to almost 305 mm long

- Compact footprint machine length 914 mm

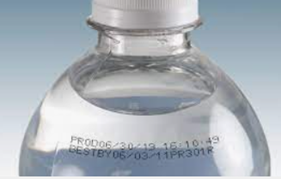

4) Date Batch Coding Machine / Trujet 55JT

- 7-inch colour touchscreen display

- Supports up to 2 print heads

- Independent controller separated from the print heads, suitable for various working environments

- Printing height up to 25.4mm (1.0″)

- Low periodical maintenance

- Clean and trouble-free technology

- User-friendly interface

- Easy integration into any production environment

- Easy adjustment for down and side printing

- Printing on porous or non-porous surface

- Ability to backup settings, logos, and messages

- User level password protection

- Automatic recognition of inks (aqueous or solvent) and application of appropriate printing parameters

- Controller stores up to 500 messages internally

- Ethernet and USB connectivity

- PC software for message template design

- Printing speed up to 60m/min (200ft/min)

- Resolution up to 600 x 600 dpi

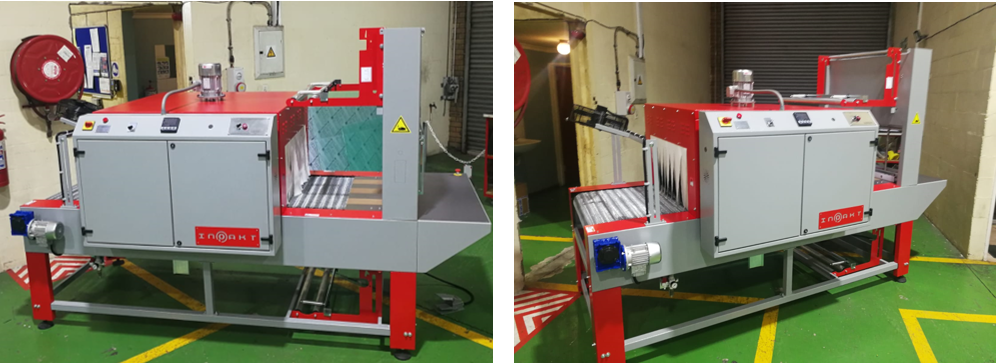

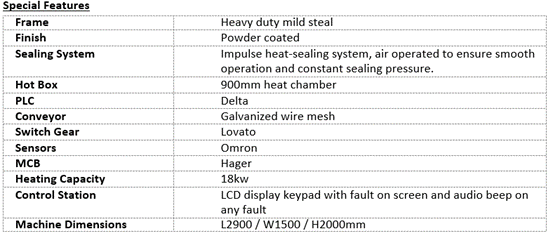

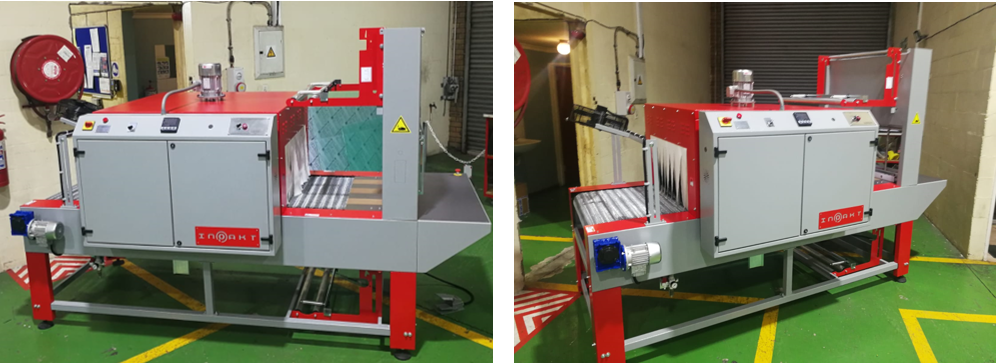

5) Semi Manual Shrink Wrapper / INPT450M

Offer to supply

Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of 850 wide x 400mm high our Model 58SM4

Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of 850 wide x 400mm high our Model 58SM4

Electrical requirement

380 Volts 3 Phase Neutral and Earth. (45 amps per phase).

Compressor requirement

Cleon source of dry air at 500 KPA (100 It. free air per minute).

BOTTLING LINE FOR LIQUIDS OR CREAMS – UP TO 1800BPH

12 Head Bottle Rinser

The bottling process begins with the empty bottles placed upside down on the rinse nozzles. The operator pushes the rinse button to start a pre-timed rinse. When the rinse stops, the operator transfers the bottle to the filling line. Then the bottles are set in place under the filling nozzles, and the operator has the option to fill with a pre-set button (adjustable), or with the manual fill button. After the bottles are filled, an operator places the cap on the top of the bottle and secures it with the electronic capper. Then the label is applied to the bottle by simply sliding it across the roll-on labeller.

- Fills 100ml to 1000ml bottles

- Capable of producing up to 1500 bottles per hour (500ml)

- Trouble free operation

- Installs in compact area

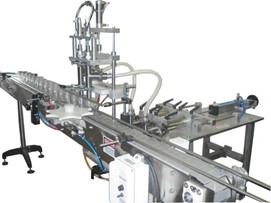

Double Head Auto Liquid Piston Filler / FLS2LP

Standard Features

· Heavy duty pneumatic product cylinder drive system

· Heavy duty pneumatic product cylinder drive system

· Integral 304-grade stainless steel base and cladding mounted on a stainless-steel trolley

· Bottom up fed nozzle assembly

· Wetted parts manufactured from 316-grade stainless steel and food grade engineering plastic

· Product piston fitted with O-ring energised Teflon/HDPE glide ring seal

· Quick connect tri-clover product inlet/outlet fittings

· All pneumatic flameproof operation suitable for use with flammable products

· Individual fill speed and recharge speed controls

· Fill volumes can be from 500ml to 5,000ml. Smaller cylinders available down to 50ml

· Product cylinder and valve dismantle by hand for cleaning, no tools required

· Filling accuracy +/- 0.5 to 1%

Automatic 2 Head Piston Filler

3m Conveyor (Stainless Steel Construction)

Automatic Bottle indexing system

Available sizes as above (always use the largest size if smaller sized change parts are needed).

All Air Logic, except conveyor motor. Suitable for Hazardous location with air drive conveyor motor.

Speed of 20 – 40 bottles per minute (speeds are determined by bottle size, product, and neck opening)

Options: Diving nozzles, Cut-off nozzles, supply tank with lid, wash down motor, and many more

Specifications

· Size 2500mm w x 1400mm d x 1700mm h

· Weight (approx.) 90kg

· Air Pressure Required 600 kPa

· Air Consumption 10C FM

· Speeds, approx. 20-40 BPM on a 500ml bottle

· Filling Range 100ml to 1000ml (double stroke for higher volumes)

Options

· Additional sizes of interchangeable product cylinder and piston assemblies

· Twin manifold and suction hose inlet

Automatic Capper with Cap Feed Hopper / CPP-118S

The Semi-Auto Chuck Capper is designed for when specific torque accuracies are needed. The operator of the machine manually places the caps on the bottles as they pass and the Semi-Auto Chuck Capper automatically tightens them. The Semi-Auto Chuck Capper uses the same chucks and inserts as are other cappers to accurately tighten caps. An electronic clutch determines how much torque is applied to each cap. Our Semi-Auto Chuck Capper’s are designed to handle most bottle types including P.E.T, P.V.C, plastic, and glass. To eliminate damage to caps and reduce insert wear, the Semi-Auto Chuck Capper comes with adjustable electronic torque values. A Conveyer and an operator are required. the operator is required to place caps on the bottles as they pass by on the conveyer. Once the caps are placed the Inpaktcapper can then secure them onto the bottles. The Semi-Auto Chuck Capper comes complete with: an A.B.I. unit, a universal stand to mount onto your conveyor one chuck, and one insert.

Specifications

Dimensions:

Dimensions:

Length:1524 mm

Depth: 914.4 mm

Height: 609.6 mm

Weight: Approx. 68.03 kg

Capping Speed: Up to 30 CPM*

Cap Size: Min: 10mm / Max: 120mm

Torque Range: 1 – 90 In-Lb

Electrical: 220 V

Air Requirements: 120 PSI @ 2 CFM

Self-Adhesive Labelling Machine Filler / LBL-450R

Specifications

- Footprint size 1600mm x 900mm wide x 1100mm height

- Label Roll 75mm inner diameter; 300mm outer roll diameter

- Power 220V 50/60Hz

- Label head stepper motor

- Emergency safety Off unbutton

- SUS#304 stainless steel and aluminum alloy frame construction

- Automated labelling for up to 85% wrap labels on straight-sided round bottles at speeds of 50-80 bottles per minute

- No adjustments needed: built-in conveyor automatically matches label speed.

- Labelling accuracy ± 1mm

- Individual label height of 12 mm (½ inch) to almost 102 mm (4 inches) tall

- Individual label width of 12 mm to almost 305 mm long

- Compact footprint machine length 914 mm

Date Batch Coding Machine / With 1.5m conveyor

- 7-inch colour touchscreen display

- Supports up to 2 print heads

- Independent controller separated from the print heads, suitable for various working environments

- Printing height up to 25.4mm (1.0″)

- Low periodical maintenance

- Clean and trouble-free technology

- User-friendly interface

- Easy integration into any production environment

- Easy adjustment for down and side printing

- Printing on porous or non-porous surface

- Ability to backup settings, logos, and messages

- User level password protection

- Automatic recognition of inks (aqueous or solvent) and application of appropriate printing parameters

- Controller stores up to 500 messages internally

- Ethernet and USB connectivity

- PC software for message template design

- Printing speed up to 60m/min (200ft/min)

- Resolution up to 600 x 600 dpi

Semi Manual Shrink Wrapper / NPT-450SM

Offer to supply

Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of 850 wide x 400mm high our Model 58SM4

Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of 850 wide x 400mm high our Model 58SM4

Electrical requirement

380 Volts 3 Phase Neutral and Earth. (45 amps per phase).

Compressor requirement

Cleon source of dry air at 500 KPA (100 It. free air per minute).

JUICE/WATER BOTTLING LINE / 330ML – 500ML AND 1500ML PET BOTTLES WITH 38MM & 2MM SCREW CAP

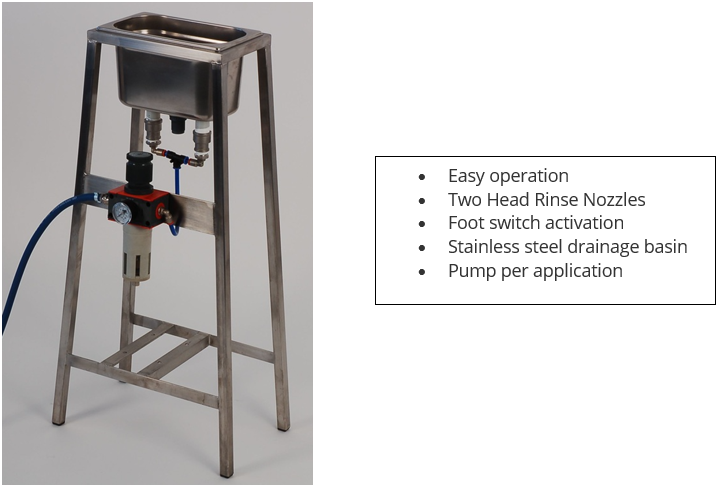

Rinsing Unit – 2 Nozzle / RCM2

The easy to operate manual wet rinser is ideal for smaller facilities that manually rinse containers prior to filling, packing or shipping. The operator of the bottle rinser simply steps on a foot-switch to activate the rinse cycle. The container is then rinsed for a preset amount of time. This type of container cleaning equipment can also be incorporated into a uni-frame liquid filling system for single station rinsing and filling.

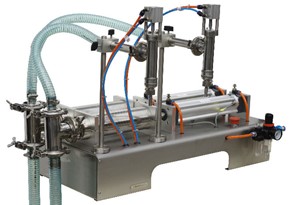

Double Head Liquid Piston Filler / FLS2

Simple to operate heavy duty design with a proven history of reliability and ease of cleaning. The versatility of this all-pneumatic machine has now been enhanced with a completely new compact design, volume adjustment and cylinder assembly incorporating air operated Spool Valves. The valve system handles products from thin liquids to creams. Cylinder design enables quicker dismantling and easier more thorough cleaning of wetted parts. Various product supply methods can be used according to the nature of product or customer preference e.g. suction hose to elevated or floor level tank, or low-pressure feed from and external pump. Ideal for use in a range of industries including Chemical and Automotive.

Specifications

·  Size 780mm w x 1400mm d x 1700mm h

Size 780mm w x 1400mm d x 1700mm h

· Weight (approx.) 90kg

· Air Pressure Required 600 kPa

· Air Consumption 10C FM

· Speeds, approx. 1000BPH on a 500ml bottle

· Filling Range 100ml to 1000ml (double stroke for higher volumes)

Options

· Additional sizes of interchangeable product cylinder and piston assemblies

· Twin manifold and suction hose inlet

Standard Features

- Heavy duty pneumatic product cylinder drive system

- Integral 304-grade stainless steel base and cladding mounted on a stainless-steel trolley

- Bottom up fed nozzle assembly

- Wetted parts manufactured from 316-grade stainless steel and food grade engineering plastic

- Product piston fitted with O-ring energised Teflon/HDPE glide ring seal

- Quick connect tri-clover product inlet/outlet fittings

- All pneumatic flameproof operation suitable for use with flammable products

- Individual fill speed and recharge speed controls

- Fill volumes from 500ml to 5,000ml. Smaller cylinders available down to 100ml

- Product cylinder and valve dismantle by hand for cleaning, no tools required

- Filling accuracy +/- 0.5 to 1%

Pneumatic Hand-held Capping Machine / CP-104

This is an easy-to-use tool for capping plastic bottles – fast. It is connected to an air compressor and is very handy and portable.

This is an easy-to-use tool for capping plastic bottles – fast. It is connected to an air compressor and is very handy and portable.

The cap is placed on the bottle and the Pneumatic Capper is pressed on the cap. It is tightened pneumatically and stops once the set torque is reached. The tightening level of the cap can be adjusted with the torque adjuster provided on the too.

Its unique features are

Being pneumatically operated, it requires very little maintenance.

Being pneumatically operated, it requires very little maintenance.- Easy to use and requires very little skill.

- It is light weight and portable.

- Uses minimum quantity of air only when it is actually capping.

- No electrical connection more reliable and longer life

Specifications

| Power | Air |

| Compressed air | 5 to 6 bar (constant) |

| Capping heads | 1 |

| Capacity | 1000 BPH |

| Cap chuck size (to be confirmed) | Most sizes and shapes – screw on |

Includes

Pneumatic Capper

Single cap chuck (for one size cap)

Retracting cord

Pneumatic hose

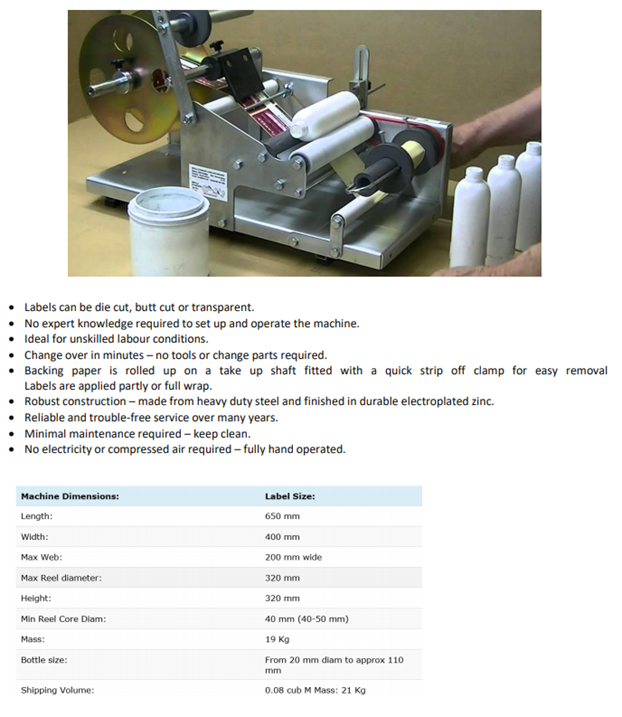

Labelling Machine for Round Bottles / LB-104

Date Batch Coding Machine / With 1.5m conveyor

- 7-inch colour touchscreen display

- Supports up to 2 print heads

- Independent controller separated from the print heads, suitable for various working environments

- Printing height up to 25.4mm (1.0″)

- Low periodical maintenance

- Clean and trouble-free technology

- User-friendly interface

- Easy integration into any production environment

- Easy adjustment for down and side printing

- Printing on porous or non-porous surface

- Ability to backup settings, logos, and messages

- User level password protection

- Automatic recognition of inks (aqueous or solvent) and application of appropriate printing parameters

- Controller stores up to 500 messages internally

- Ethernet and USB connectivity

- PC software for message template design

- Printing speed up to 60m/min (200ft/min)

- Resolution up to 600 x 600 dpi

Semi Manual Shrink Wrapper / INPT450M

Offer to supply

Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of 850 wide x 400mm high our Model 58SM4

Electrical requirement

380 Volts 3 Phase Neutral and Earth. (45 amps per phase).

Compressor requirement

Cleon source of dry air at 500 KPA (100 It. free air per minute).

Being pneumatically operated, it requires very little maintenance.

Being pneumatically operated, it requires very little maintenance.

Reviews

There are no reviews yet.