Description

Infeed, Air Conveyor

Air conveyor is supported on the ground, with air fan installed above the conveyor. Air filter is installed in Air conveyor is supported on the ground, with air fan installed above the conveyor. Air filter is installed in the door of every fan, to avoid dust blown into bottles. Bottles are retained by neck supporting carrier plate in the conveyor, and transported into filling monoblock.

⦁ Type: F-9

⦁ Power: 2.2KW/set

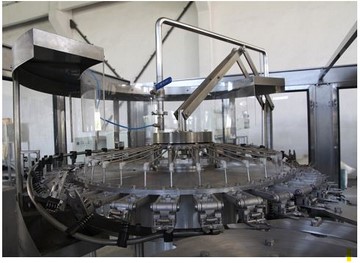

Bottle Rinser, Filler and Capper

⦁ Type: HGF14-12-5

⦁ Type: HGF14-12-5

⦁ Working location: rinser 16, filler 14, capper heads 5

⦁ Production capacity: 2500LPH (1000ml 30/25mm bottleneck)

⦁ Air source pressure: 0.7MPa⦁ Air consumption: 0.8M3/min

⦁ Rinsing water pressure: 0.2-0.25 MPa

⦁ Rinsing water consumption: 1.2 t/h

⦁ Filling way: gravity filling

⦁ Host power: 2.2KW

⦁ The total capacity: 3.12KW

⦁ Voltage rating: 380V

⦁ Dimension: 2760*2060*2700mm (L*W*H)

Rinsing Station:

Filler And Capping Station:

⦁ High precision filling nozzle, PLC variable signal control, ensure high filling precision

⦁ High precision filling nozzle, PLC variable signal control, ensure high filling precision

⦁ Gravity filling⦁ All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

⦁ No bottle no filling

Bottle Cap Washer, Sterilizer

The System is used to sterilize and wash the plastic caps before capping by disinfectant water and clean water. The System is used to sterilize and wash the plastic caps before capping by disinfectant water and clean water.

System included:

⦁ Sterilizing tunnel and washing tunnel 1pc

⦁ SUS316L disinfectant water pump 1pc

⦁ SUS304 clean water pump 1pc

⦁ Recycling tank 200Liter 1pc

⦁ Caps elevator 1pc

Feature:

Automatic caps sorting

feeding, sterilizing

caps and washing.

Under PLC control lack of caps automatic feeding full of caps automatic stop.

Without caps automatic stop.

SUS304 construction and clear FRP cover

easy maintain

Basic parameter

Item Parameter

Disinfectant water spray time 20 seconds

Clean water spray time 20 seconds

Spraying tunnel length 3meter

Power 0.75kw

Air Knife – Bottle Dryer

Function:

to dry the bottle that feeding from the Rinser Filler Capper with blowing air, make them suitable to the post-packagingfeeding from the Rinser Filler Capper with blowing air, make them suitable to the post-packaging

Multiple groups of Air knife make sure bottle Complete dry. SUS304 machine construction

Technical Parameter

Vortex style air pump 1pcs

Power: 3kw

Max air flow rate: 210cube meter per pump

Max. Air Pressure 28kpa

Power Supply: 380V 3phase, 50HZ

Size: 1000*900*1700mm

Date batch ink jet coding machine

Elfin II (single head)

Controller (7″ touch screen)

Elfin II print head x

1 Deflector component (singlex1)

Bracket + Power Adaptor cable (120cmx1) U disk + Grounding Cable

Hot melt OPP wrap around Labeling System

Hot melt glue labeling machine is also called OPP/BOPP labeling machine. RR1045 is the 3rd generation inline hot glue labeler, with 4 labeling positions, the machine can work at the speed 3000~12000 bottles per hour (500ml). It is widely used for round shape and 0.1~2 liters bottles for juice, soda/mineral water, carbonated drink etc.

This machine can cut OPP、BOPP、plastic and paper labels to meet different requirements.

Advantage of the hot melt glue labeling machine

(1) High labeling precision 0.5~1mm.

(2) Steady and constant labeling.

(3) Reliable and Simplicity gluing system, safety and good performance.

(4) Reliable and steady labels cutting system, no need to adjust the cutter again and again.

(5)The cutter is available for OPP、BOPP、plastic and paper labels,

(6) Each piece of labels cost much lower than sleeves labels and sticker labels.

(7) Simplicity design, good appearance.

Parameters

Items Full Auto Linear Hot Melt Glue Labeling Machine

Power supply 380V±10%

Total power 6KW

Labeling type Wrapping round, labels in roll

Bottles Round ∮45-100mm , Height80-350mm

Label sizes Length 135-300mm, height 20-150mm

Glue coating Two ends of the labels, 10mm

Labeling precision ±0.5~1mmCapacity 6000BPH(500ML)

Glue consumption 30~40Thousands bottles need about 1kg(labels height 50mm)

Compressed air MIN5.0bar MAX8.0bar

Air consumption 0.2M³/min

Total weight 1000kg

Machine sizes L=2650 W=1370 H=1800 mm

Conveyor & Accessories

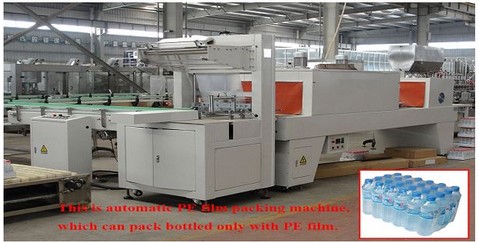

PE shrink wrap machine

⦁ Suitable to PE PVC film packaging.

⦁ Suitable to PE PVC film packaging.

⦁ PLC control system, automatic working.

⦁ Colorful touch-screen control panel, easy operate.

⦁ Bottle entering, Auto unscrambling bottle, Pushing bottle, Heat sealing-Saw cutting, Pressing PE, Shrink, Cooling automatically

⦁ Capacity is adjustable through adjust the convey speed

⦁ The height of the conveyor shall be made towards client’s demand, can handle 6, 9,12,15, 18, 20, 24 bottle per package

⦁ Double air blowers, guarantees the temperature balance in the shrink stove with PAD temperature controller that apparently saves energy.

⦁ The height of the conveyor shall be made towards client’s demand.

⦁ Heavy duty coated iron machine construction

⦁ It applies wing shape stainless steel heating system, which is durable for long time use.

Technical Parameters

Item Parameter

Capacity: 10bundles per minute

Suitable to Plastic Thickness 0.03— 0.15mm

Max packing dimension L×W×H(mm) 600×400×350

Heating Tube Temperature 260 ℃ adjustable

Shrink time/temperature 0.5-1.5s/0-260℃

Working Air Pressure 0.6-0.8Mpa, 0.8cube meter air per minute

Sealing Time needed & temperature: 0.5 to 1.5 sec, 140oC-160oC

Machine Dimension L×W×H(mm) L5500mm×W3200mm×H2100mm

Total Power: 19Kw

Power Supply 380V 50hz 3phase

Pallet wrapping machine

specifications

Work way Semi-automatic (PLC)

Max Packing height 2100mm

Max Packing Weight 2000kg

Max Packing Product L1400mm*W1400mm*H2100mm

Power AC 380V/50Hz, three phase

Turntable Speed 13rotate/min

Turntable Diameter 1500mm

Turntable Height 110mm

Dimension L2600mm*W1500mm*H2650mm

Weight 750kg

Tension control Mechanical Brake

Specifications & Price Calculation