Description

Gummy line

1. GENERAL CONDITIONS

INPAKT GROUP. HEREBY OFFERS TO FURNISH THE FOLLOWING DESCRIBED MACHINERY AND EQUIPMENT, AND/OR SERVICES UNDER THE TERMS AND PRICES AS STATED BELOW, AND IN ACCORDANCE WITH CONDITIONS SET FORTH ON THE LAST PAGE OF THIS PROPOSAL.

THIS PROPOSAL WILL REMAIN IN EFFECT FOR 60 DAYS UNLESS CHANGED IN INTERIM BY WRITTEN NOTICE FROM INPAKT GROUP. THIS CONTRACT TRANSMITTED BY EMAIL CONSTITUTES A LEGAL DOCUMENT.

2. PROJECT SCOPE

2.1 PROJECT SPECIFICATIONS

PRODUCT

|

Gummies / Pectin, Gelatin or Carrageenan |

| SYSTEM THROUGHPUT |

Up to 10000 gummies p/hour. (smallest unit we have from this specific supplier) |

| PRODUCT FEEDING |

Depositor |

| PRODUCT DISCHARGING |

Moulds into drying racks |

2.2 CONTAINERS SPECIFICATION TABLE

| # |

Product |

Form |

Dimensions (mm) |

Fill Volume |

Description |

| 1 |

Gummies |

|

|

Up to 4.5ml |

|

3. PROPOSED SOLUTION

3.1 SYSTEM TECHNICAL DESCRIPTION

| MACHINE PARTS |

All the product contact parts are stainless steel AISI 304 . The machine is constructed of

stainless steel, anodized aluminum and plastic. |

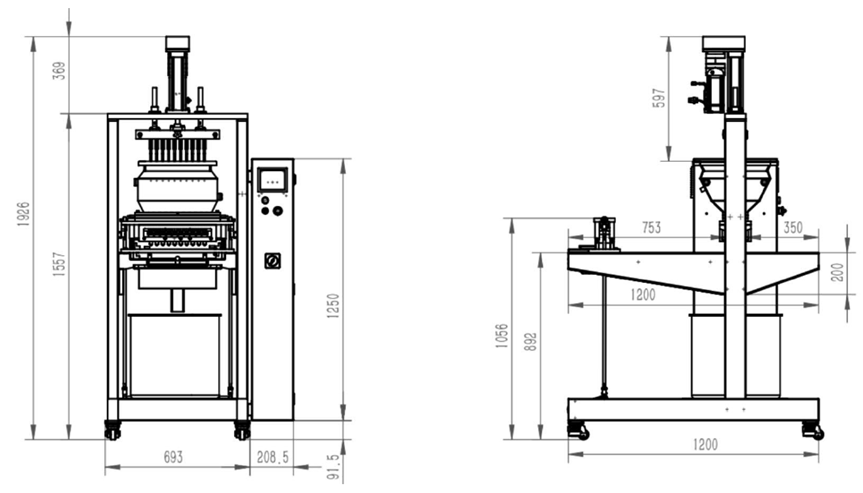

| MACHINE DIMENSIONS |

1100 x 1200 x 1557mm (L x W x H) |

| UTILITIES |

220V / 1hp / 60Hz |

| OUTPUT |

UP to 10 000 pieces per hour |

3.2 DESCRIPTION

Sheet molds under depositing nozzles. Operator feeds molds onto conveyor from front, cleated conveyor will present them to nozzles for filling and to rear off belt and onto holding plate until removed by operator. Rated at up to 25 deposits per minute or 10,000 deposits per hour. Programmable for up to three (3) deposits per mold pocket. All FDA approved product contact parts. Ten (10) depositing nozzles for fill volumes from 0~4.5ml with precision servo drive pump capable of +/- 2% weight variation. HMI control system with 20 different product setting memory banks. 7 Liter hopper with variable heating controls: 30~150°C. Voltage: 230V/1ph, Machine Weight: 60kg, Machine Dimensions: 590 x 400 x 450mm (L x W x H). Round tube sanitary frame. Portable with locking casters.

3.3 COMMERCIAL OFFER

| MACHINE

|

SPECIFICATION

|

PICTURES |

PRICE |

| COOKING KETTLE |

20 Liter Cooking Kettle with bottom and side scraping. HMI control system with 20 different product setting memory banks, variable speed mixing and heating (up to 180°C), cooling system, tilt forward discharge or front bottom butterfly valve discharge, safety interlocking lid. On round tube sanitary frame. Portable with locking casters.

220v/1ph/60hz |

|

R 291 600.00 |

| FULLY AUTOMATIC TABLETOP SERVO DEPOSITOR |

Output:6,000-10,000 gummies/hr.

• Entry-level operations or experimental and development work in larger operations.

• The DD-20 deposits a high quality, smooth product with a consistent size and shape, and high piece weight accuracy.

• The hygienic, starch-free process is ideal for pharmaceutical products where validation is required.

• Vitamins, minerals, CBD, fibre and energy supplements can be incorporated and can be sugar-free and less than

1% fat. |

|

R 675 600.00 |

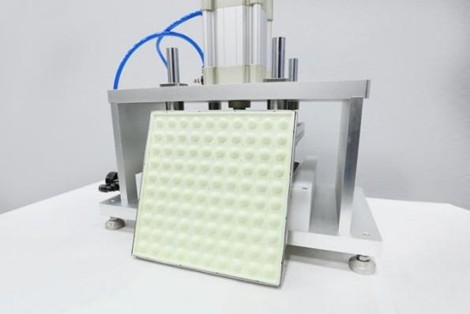

| SEMI-AUTOMATIC PNEUMATIC DEMOLDING STATION |

Semi-Automatic Pneumatic De-moulding Station. Place reinforced silicone mold onto platform, press pneumatic discharge buttons (requires both hands for operator safety) and gummies eject onto tray below. |

|

R 179 520.00 |

| SILICONE REINFORCED MOLDS

X 100 |

Molds are 300 x 300mm (100 Pocket Standard),

stiffened with internal 316 stainless structure for easy handling.

Shape can be customized

|

|

R 8 500.00 |

| DRYING TRAYS & DOLLY

20 TRAYS P/DOLLEY

60 x TRAYS

4 x DOLLEY

|

Drying Trays &Dolly

Plastic Reinforced Trays. Load Gummy2.5-3kg/tray

Mesh Bottom and Side for Even Drying

Food grade, meet FDA standard

Smooth Finish for Ease of Cleaning

Drying Tray Dolly

Stack up to 50 Levels

Stainless Steel Construction |

|

R 73 508.00 |

| COATING PAN

OIL SPARY

SYSTEM

50-70 KG/HOUR |

Pan and driving system

frame and cover

controlling system

Oil tank with belt heating 30L

Conveyor piping and control systems

Oil syrup sprayer |

|

R 179 800.00 |

| FLOWRAPPER

|

Packing speed 35-300 P/min

Width of film 80-400 mm

Making bag size (Double low cutter) L 60-200, W 40-160, H 5-50 (mm)

Packing material OPP,PE, PVC,OPP/CPP,KOP/CPP,ALU-FOIL

Thickness of film 0.03-0.1mm

Total power 5.1 KW

Power supply 1 Ph. AC220V, 50/60Hz

Machine size L4000 × W900 × H1350mm

Net weight 400kg

|

|

R 245 000,00 |

| INSTALLATION AND COMMISSIONING |

Commissioning and training for 2 days, 8 hours a day R1200 per hour |

|

Included |

Premade bagger

1. GENERAL CONDITIONS

INPAKT GROUP. HEREBY OFFERS TO FURNISH THE FOLLOWING DESCRIBED MACHINERY AND EQUIPMENT, AND/OR SERVICES UNDER THE TERMS AND PRICES AS STATED BELOW, AND IN ACCORDANCE WITH CONDITIONS SET FORTH ON THE LAST PAGE OF THIS PROPOSAL.

THIS PROPOSAL WILL REMAIN IN EFFECT FOR 60 DAYS UNLESS CHANGED IN INTERIM BY WRITTEN NOTICE FROM INPAKT GROUP. THIS CONTRACT TRANSMITTED BY EMAIL CONSTITUTES A LEGAL DOCUMENT.

2. PROJECT SCOPE

2.1 PROJECT SPECIFICATIONS

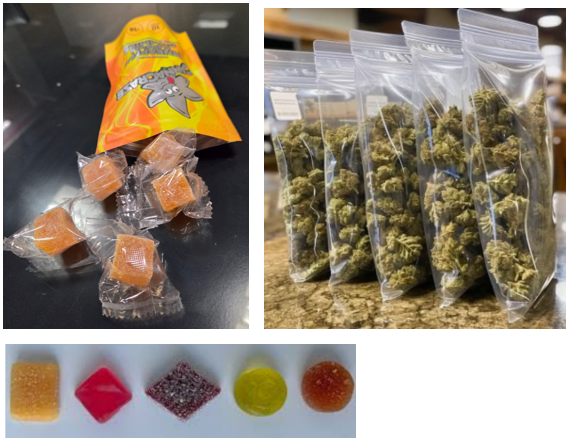

| PRODUCT |

Medical cannabis flower & Gummies |

| BAG WIDTH |

80mm – 200mm |

| BAG LENGTH |

100mm – 30mm |

| SEALING STYLE |

Heat seal & zipper seal |

| SYSTEM THROUGHPUT |

Up to 40 bags/per minute. |

| PRODUCT FEEDING |

Multihead weighing system |

| PRODUCT DISCHARGING |

Outfeed conveyor |

| PNEUMATIC |

All Pneumatic components are “AIRTAC” Taiwan |

2.2 CONTAINERS SPECIFICATION TABLE

| # |

Product |

Form |

Bag Dimensions (mm) |

Fill Volume |

Description |

| 1 |

Cannabis flower & Gummies |

Premade bag |

80mm-200mm |

5 – 50 gummies |

Plastic premade bag |

3. PROPOSED SOLUTION

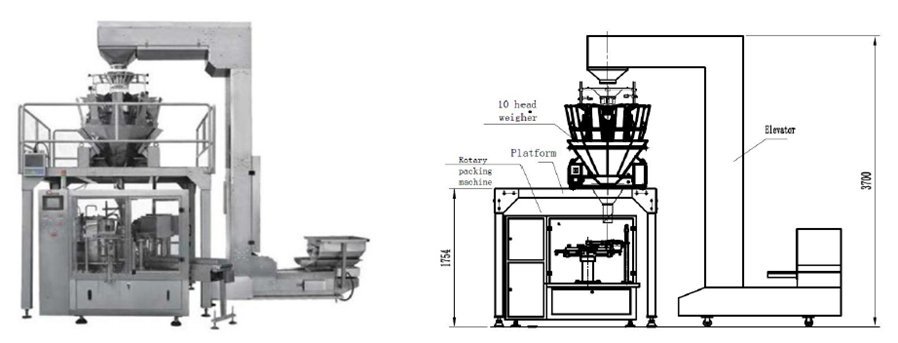

3.1 SYSTEM TECHNICAL DESCRIPTION

| MACHINE PARTS |

All the product contact parts are stainless steel AISI 304 . The machine is constructed of

stainless steel, anodized aluminum and plastic. |

| AIR CONSUMPTION |

Air consumption – <0.4m³/min |

| MACHINE DIMENSIONS |

LxWxH 4500 x 3000 x 3700mm. |

| UTILITIES |

Pneumatic air required, not included in the price |

| DRAWING |

Attached |

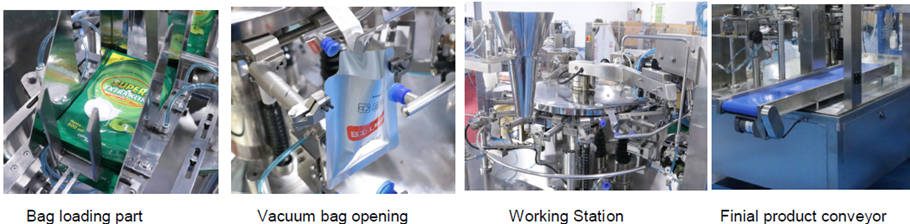

3.2 MACHINE SEQUENCE OF OPERATION

3.3 COMMERCIAL OFFER

| MACHINE

|

SPECIFICATION

|

PICTURES |

PRICE |

| ROTARY PACKER

(AUTO SIZE ADJUST) |

Construction: SS 304

Bag width:80-200mm

Bag length:100-300 mm

Speed: 10-40 bags/min

No of working stations: 8

Compress air requirement: <0.4m³/min

Power: 380V,3P, 50Hz ,4KW

Dimension: 1470mm x1580mm x1486mm

Including:

Plexiglass Tent

Vacuum pump

Free quick wear spare parts

Finished product transport belt |

|

|

| SERVO ZIPPER BAG OPENER |

Servo motor

Used for opening the zip bag |

|

Included |

| BAG TAPPING DEVISE |

Material: SS 304

Pneumatic

To assist with feeding the product |

|

Included |

| BAG BLOWER |

Material: SS 304

Pneumatic

Helps open bag fully

|

|

Included |

| DATE CODING MACHINE |

Consumable: Ribbon

Size: 35mm x 100mm

Color: Black

Max lanes: 2 lines with 14 letters

Used for production/ expiration date Printing.

|

|

Included |

| BAG BOTTOM OPENING DEVICE |

Material: SS 304

Pneumatic

Used to help open the bag bottom |

|

Included |

| AIR REMOVAL SYSTEM |

Material: SS 304 + Sponge

Pneumatic

Used to remove the air from the bag |

|

Included |

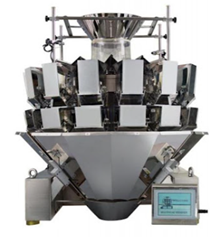

| 14 HEAD WEIGHER |

Weigh head Nos: 14 head

Material: SS304

Working voltage: 220V, 1P, 50Hz, 1.1KW

Hopper Volumne: 0.5 L

Machine weight: 200kg

Packing range: 2-200g (±0.1-1g)

Max speed: 100 bag/min

Size: 1190mm x 970mm x 960mm

Including:

German HBM sensor

Used Weighing & Filling

|

|

Included |

| ELIMINATE DISCHARGE DEVICE |

Usage: Overflow outlet |

|

Included |

| WEIGHER PLATFORM |

Material: SS 304

Size:2000mm x 2000mm x 1800mm

Used for support the10 head weigher |

|

Included |

| Z type bucket elevator |

Material: SS 304

Voltage:220V / 1P / 50Hz / 0.75kw

Hopper size: 650mm x 650mm, 70L

Transport hopper capacity: 1.8L

Transporting capacity: 4-6m3/h

Size: 3172mm x 650mm x 3600mm

Used to auto feeding product into weigher |

|

Included |

| INSTALLATION AND COMMISSIONING |

· Commissioning and training for 4 days, 8 hours a day R1200 per hour |

|

Included |

Data-sheet_DD-20-Small-Batch-Depositor-

Updated list of molds for desktop candy casting machine, version 2026 (12-18) (1)

Reviews

There are no reviews yet.