Description

RETORT & BOILER

SCOPE OF OFFER: –

3 Basket steam retort with steam boiler

Equipment list:

1 x Boiler

1 x Retort

Diesel type steam boiler

Features:

• The burner is supplied by Baltur, Italy.

• Quick start-up, can reach high temperature and pressure in short time.

• Nature circle, could handle large temperature change.

• With multi chain protection for water level and steam pressure.

• Vertical structure, small footprint, space saving and easy installation.

Technical parameters:

| Model: | INP-GL3000 |

| Steam Capacity | 3000 Kg/h |

| Rated working pressure | 0.7 Mpa |

| Real Working pressure | Can be adjusted |

| Hydraulic testing pressure | 1.05 Mpa |

| Diesel | 100 Kg/h |

| Thermal Efficiency | 92% |

| Power Supply | 400V / 50HZ / 3P |

| Saturated steam temperature | 170℃ |

| Main steam valve diameter | 40 DN |

| Safety valve diameter | 40 DN |

| Water in diameter | 25 DN |

| Sewage valve diameter | 25 DN |

| Chimney diameter | 250 DN |

| Overall dimension L*W*H) | 2530*1980*2650 mm |

3 basket Retort model 3INP-1300R

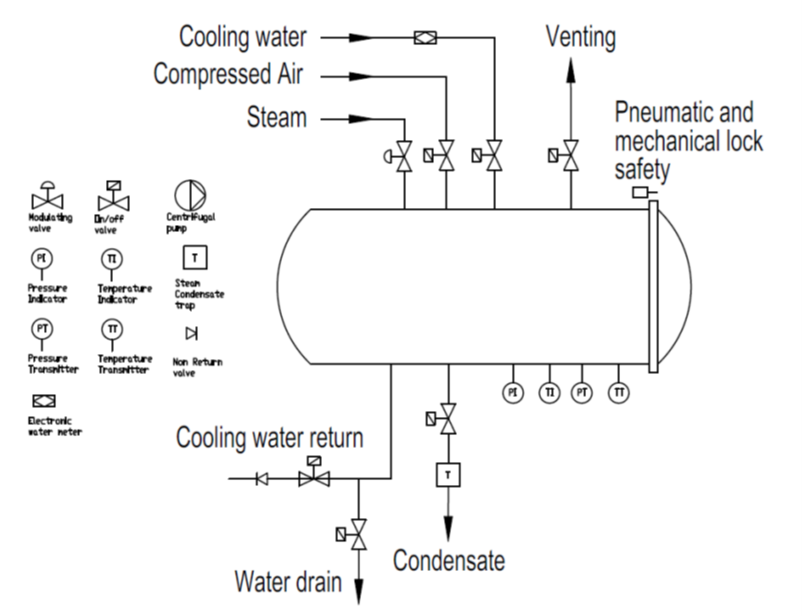

Retort P&ID:

Control system:

- A retort is a pressure vessel designed to sterilize containerized food.

- The Control system will automatically control temperature and pressure by maintaining the

safety parameters. - The Steam-Air retort is suitable for canned product.

- Special perforated layer pads ensure good steam and water flow between product layers.

- The basic process:

- Load Product and close door

- Select Process time and temperature – Start process

- A Pneumatic piston devise will lock the door and process will not start if signal from an

additional proximity sensor indicates that door is locked - Steam control valve opened and vent valve opened

- Venting continuous until a certain temperature is reached to ensure most air is vented out the vessel. Required for good heat transfer.

- The Cook cycle starts when vent valve is closed

- A 4-20mA steam modulating valve ensures accurate temperature control

- At end of heating process, the steam valve is shutoff and cold water is slowly introduced via an on/off valve

- As the steam collapses, compressed air can be introduced to prevent cans peaking especially during start of the cooling cycle. This becomes more important when running large can sizes.

- Water is metered into the vessel via electronic meter to know when it is filled.

- Water will be pushed back to the Cooling water system with compressed air (Return pump can be supplied if required instead)

- Water can be circulated through the retort for cooling if required (pump supply to be discussed in this case)

- After cooling, water will be pushed back to Cooling water system or drained.

- Process complete and deactivate Pneumatic piston and open mechanically

- Unload product

- All temperature and pressures will be automatically logged and stored for traceability and record keeping.

- All parameters will be displayed on a Colour touch screen

- All critical measuring instruments will have calibration certificates

- SFB Engineers can provide heat distribution in the retort and heat penetration trial into the product, if required.

Mechanical Specification:

- 3 -basket static horizontal retort manufactured from 430A boiler plate.

- Diameter 1300mm complete with bayonet type door

- Instrument box

- Pneumatic and mechanical connection for the door lock

- Steam control 4-20mA modulating valve

- Vent valve

- Compressed air inlet

- Water inlet valve

- Water drain

- Condensate trap

- Thermometer

- PT100

- Shut off and one-way valves

- Dial Pressure gauge 0 – 4 bar

- Dial Temperature gauge

- Engineering drawing, supervision and tests will be done by Indserve cc, an approved inspection authority on pressure vessel

- Stainless steel retort baskets and trolleys:

- WxLxH = 850x900x900 mm inside dimensions.

Electrical Specification

- Control Panel MCC in Epoxy coated Stainless steel

- Controller Hardware and components:

- Remote communication hardware

- HMI Hardware: 4.3″ Colour touch screen

- Control System Configuration

- Software Design & Documentation

- Stainless steel rod cable runways and cabling

- Factory Acceptance Testing in house

| Retort equipment list |

| RETORT MODEL 3INP-1300R (Steam-Air) |

| Mechanical |

| Retort shell diameter 1300mm – 3 basket |

| Vent – fast acting pneumatic valve |

| Steam Modulating control |

| Pneumatic Shut off valves |

| Non return valve |

| Compressed air inlet fast acting pneumatic valve |

| Water inlet pneumatic valve |

| Water drain pneumatic valve |

| Condensate trap |

| Dial Thermometer |

| Dial Pressure gauge 0 – 4 bar |

| PT100 temperature probe |

| Pressure transmitter |

| Electronic water meter |

| Pipework labour |

| Pipework material |

| Electrical Control |

| Control Panel MCC in Epoxy coated Strainless steel |

| Controller Hardware and components: |

| 4,3 Inch Colour display and programming |

| Control System Configuration |

| Software Design & Documentation |

| Stainless steel wiremesh cable tray and cabling |

| Factory Acceptance Testing in house |

| 6 of Heavy duty retort trolleys, removable baskets (stainless steel) and Polyprop layerpads |

Reviews

There are no reviews yet.